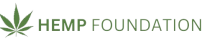

Our history with textiles started 34,000 years ago with the fibre material flax fibre. And it’s no secret that a lot has changed over the last 34,000 years.

The last 500 years of the textile industry have been well-catalogued. The history of textiles tells us how the global apparel market rose to 1.5 trillion USD in 2021.

And not to mention, how the clothes in our cupboards became one of the major contributors to climate change by being responsible for 8-10% of global emissions.

In this article, we will cover:

- Textile industry in the pre-industrial revolution (1500-1800)

- Textile industry trade

- Silk pattern

- Technical innovations

- Textile industry in the industrial era (1750-1900)

- Understanding the transition

- Key events of the time

- Modern textile industry (1900-2022)

- The birth of fast fashion

- The digital revolution

- The move to sustainable fashion

- Hemp textile

Textile Industry in The Pre-Industrial Revolution (1500-1800)

Textile industry trade

The beginning of the 16th century was the golden age of European maritime navigation. You might already know about the spice routes but during this period there was also a huge variety of textiles being traded.

Fun fact: These textiles were actually direct currency for spices.

Textile trade was happening all around the world.

From the ‘Age of Discovery’ to the 19th century, India’s painted and dyed cottons, the silks of China and Japan, Turkey and Iran were exported westward to Europe and the Americas.

What the world saw was the birth of worldwide visual culture, and the emergence of the first truly global style.

Silk Pattern

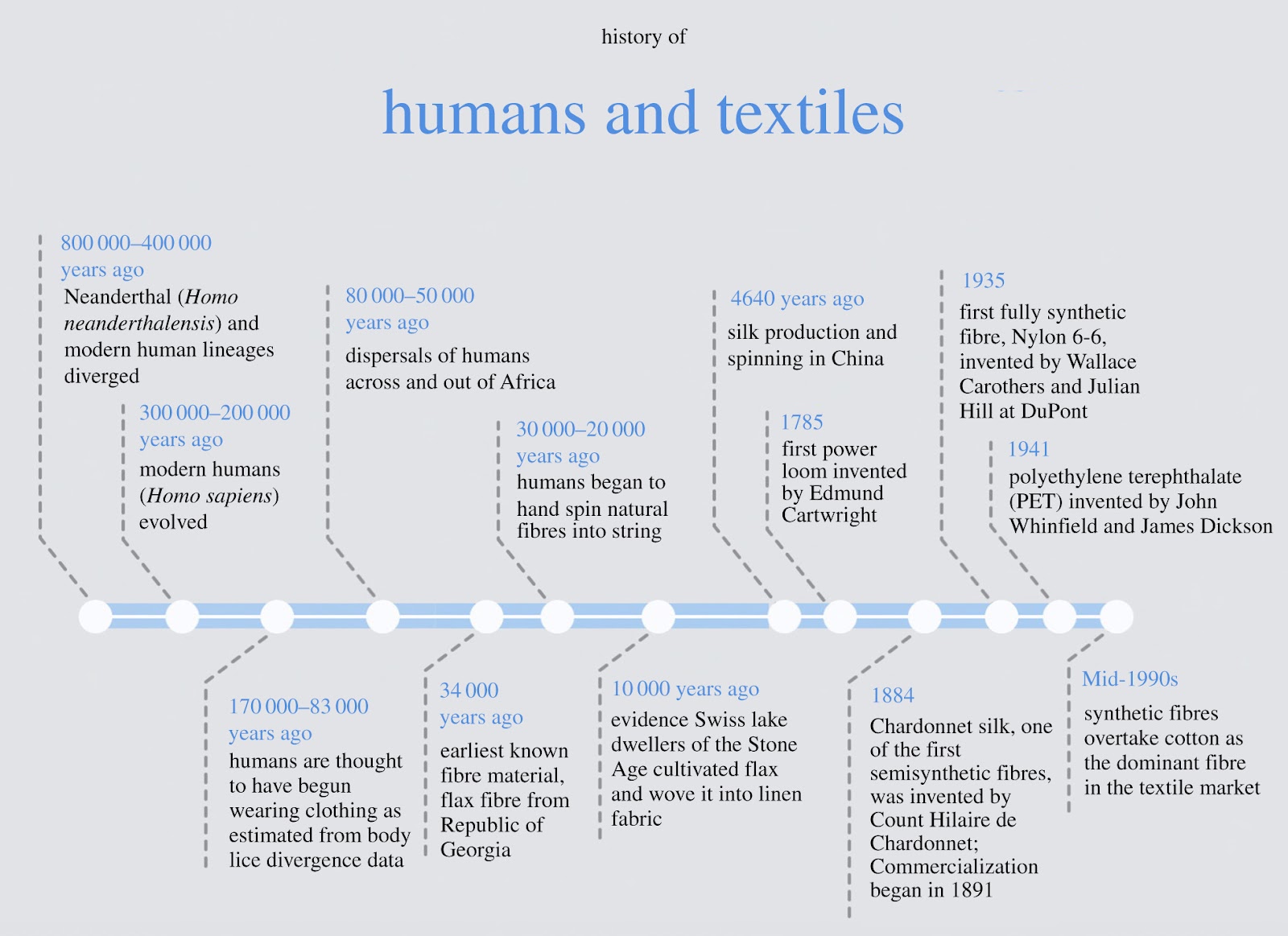

Another important historical landmark was the creation of patterned silk textile. The patterned silk velvet was the most expensive and prestigious of all woven textiles.

In France, 15th century onwards, the silk-weaving inserted had grown. The same growth was witnessed in Italy. Almost 15,000 workers in Lyon were involved in the silk industry either directly or indirectly by the late 18th century.

Technical innovations

The intersection of technology with goods is always a crucial part of history. It helps us understand how our factories reached where they are.

The late 18th century witnessed exponential growth in technology when it came to textiles.

Philippe de Lasalle (1723–1804), a designer, weaver, and entrepreneur working in Lyon, invented a removable version of a device called a semple. This sped up the process of loom preparation and weaving.

The innovation also paved the way for the development of the Jacquard loom in 1801. This loom reduced the labour required. It could be programmed to weave even more complex patterned textiles without the aid of a second worker.

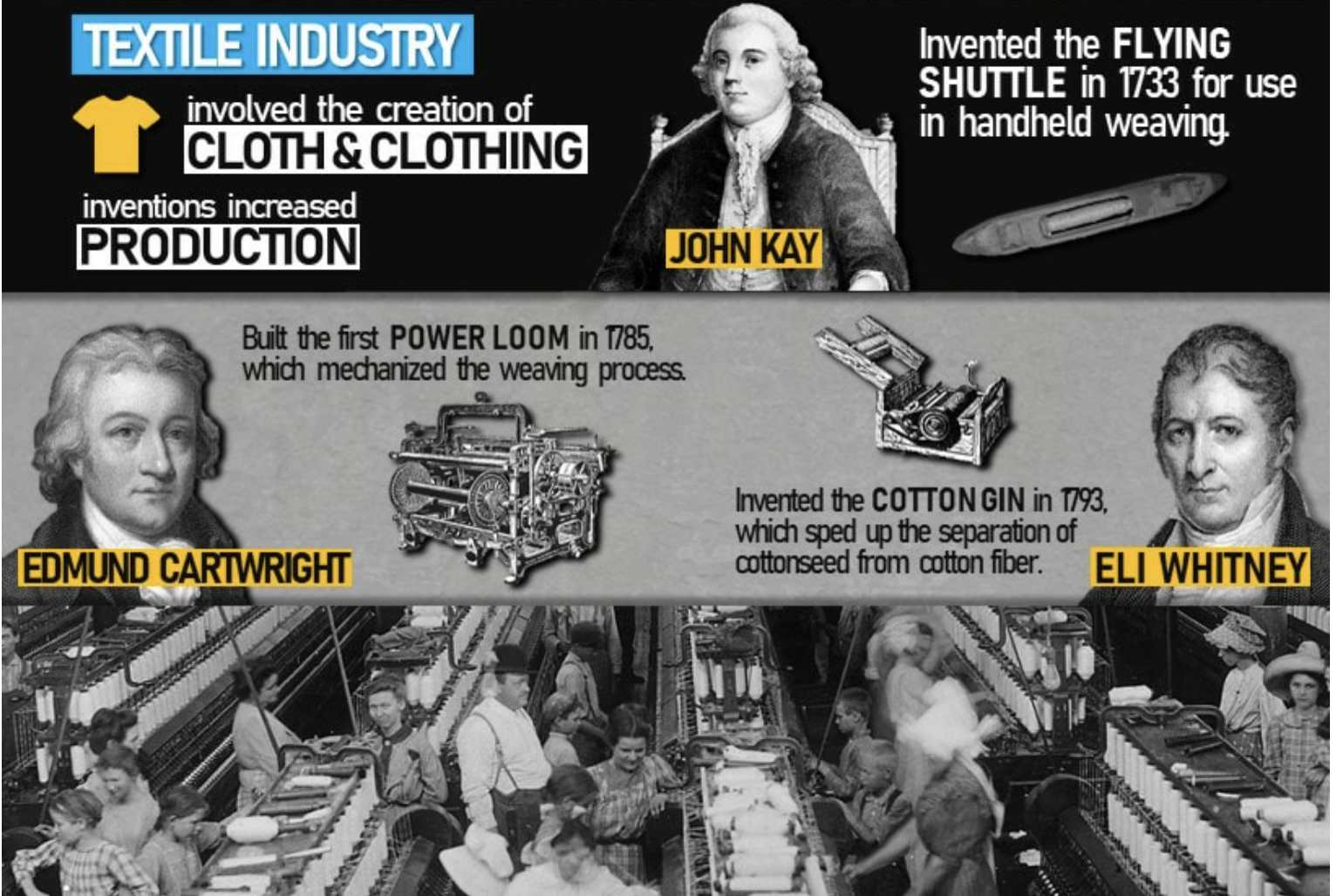

Around the same time, Edmund Cartwright in England was working on the first wool-combing machine. The intervention of this power loom in 1785 was what created the power loom that we know today.

The textile industry in the pre-industrial era was influenced by culture, trade, money, and science and technology. Let’s move on to see the technology that pushed us into the industrial era.

Textile industry in the Industrial era (1750 – 1900)

Textile industry in the industrial era was closely connected to colonialism. With textile being traded into different parts of the world, technology to make the textile was also reaching these areas.

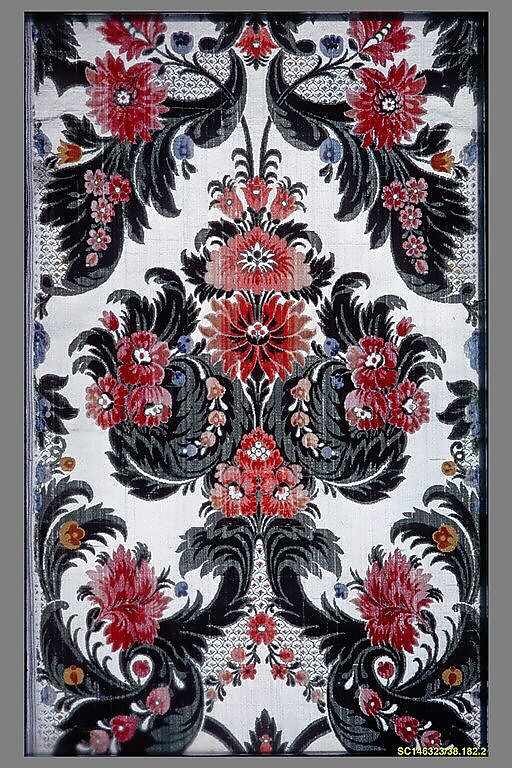

Understanding the transition

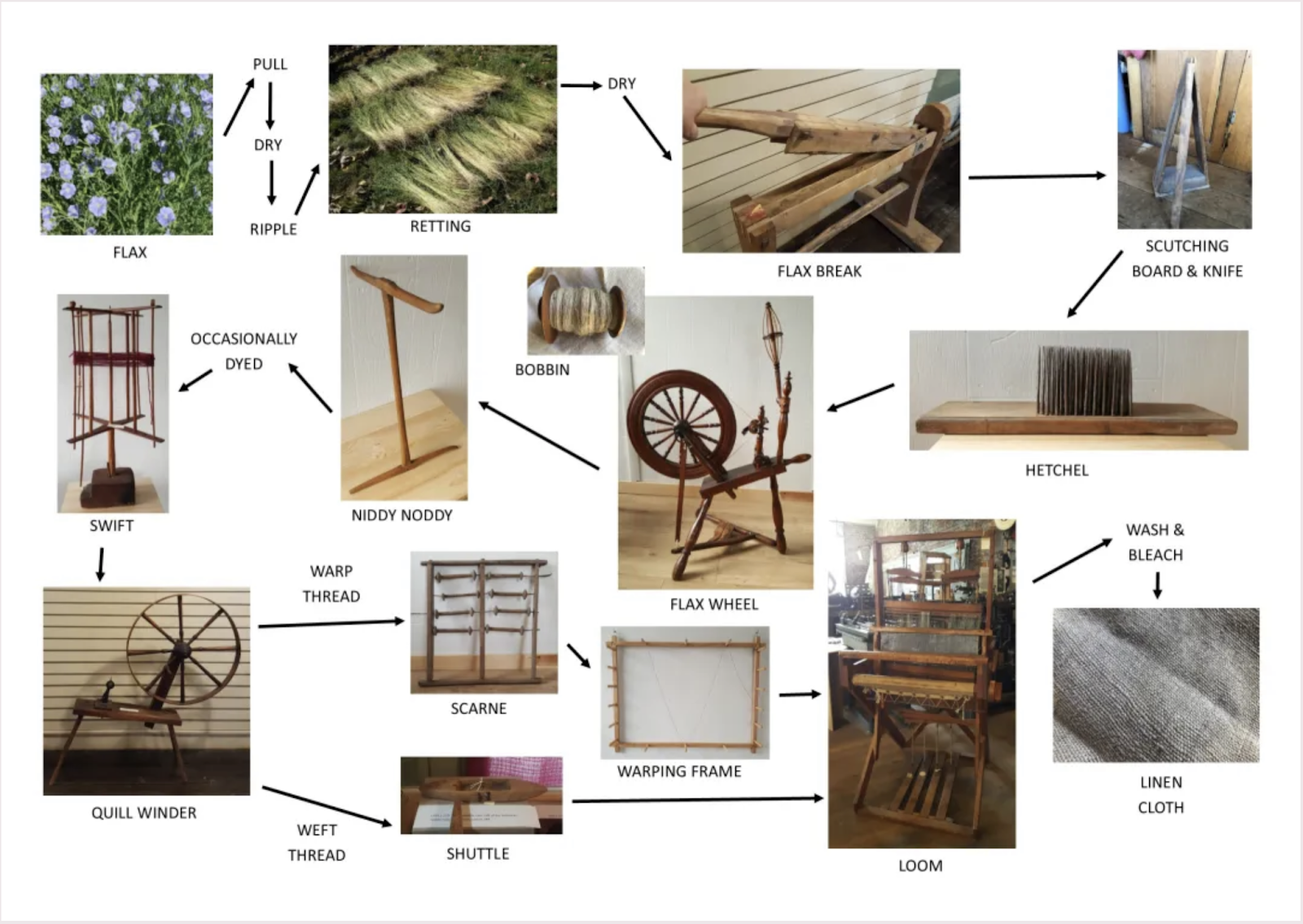

Before the invention of machines, making thread, yarn, and cloth by hand was a laborious and complex process. We needed skilled spinners and weavers. They used a large number of small, mostly wooden, preindustrial devices and machines.

Key events of the time

As the infographic illustrates, the technological innovations in the textile industry weren’t isolated. At the same time, there were other innovations like the steam engine and the steam train that allowed the transportation of these textiles.

- 1764 – James Hargreaves invented the Spinning Jenny, the first powered textile machine which was patented in 1770. Hence, the notion of the technology belonging to someone came into place.

- 1769 – Arkwright patented the water frame.

- 1773 – The first all-cotton textiles were produced in factories.

- 1779 – Crompton invented the spinning mule. It allowed greater control over the weaving process.

- 1813 – William Horrocks improved the power loom by introducing variable speed batton.

- 1787 – Cotton goods production had increased 10 fold since 1770.

- 1789 – Samuel Slater brought textile machinery design to the US.

- 1790 – Arkwright built the first steam-powered textile factory in Nottingham, England.

- 1792 – Eli Whitney invented the cotton gin. The machine automated the separation of cottonseed from the short-staple cotton fibre. The fabric became a cheaper alternative to silk. Linen, wool and hemp fabrics also emerged as other cheaper alternatives.

- 1804 – Jacquard Loom was invented. The machine automatically controls the warp and weft threads on a silk loom by recording patterns of holes in a string of cards.

- 1856 – William Perkin invented the first synthetic dye.

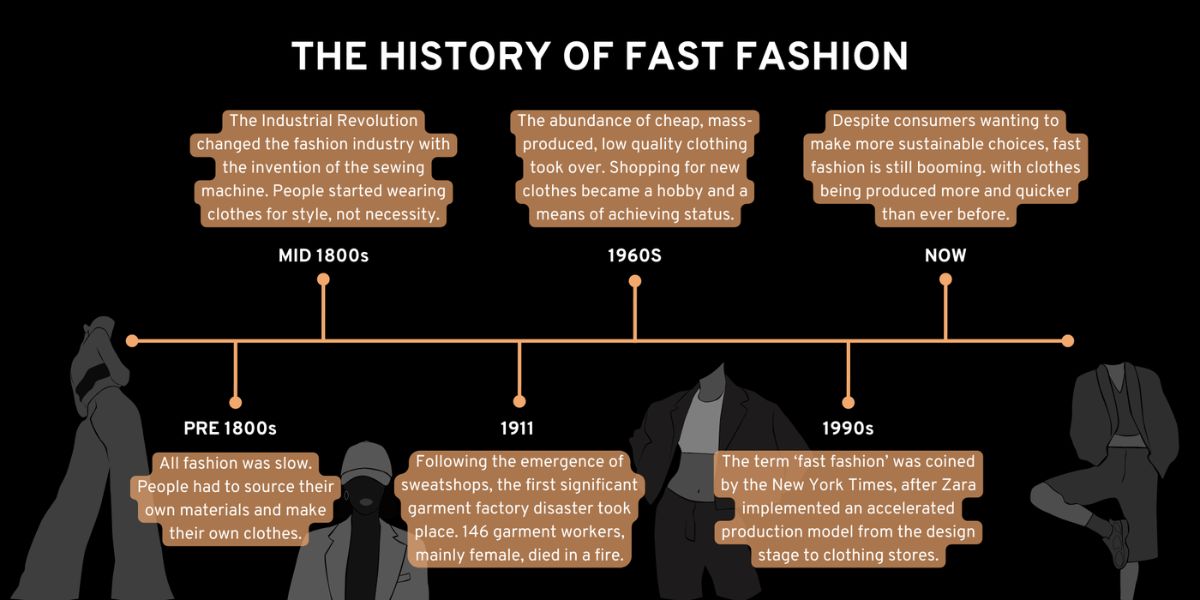

During the industrial revolution, the cottage industry was replaced by the factory system. This means that small-scale production of textiles was replaced with the factory system. Which meant, more textiles were produced in less time.

Modern textile industry (1900-2022)

In the modern world, textile production has reached a whole new level. With new technology, the production process was faster than ever. And over the years, technology progressed even more.

Electrical energy was discovered which allowed us to create synthetic fibres. To make the process more efficient, we came up with new fabric-cutting and dyeing technologies. The cultural value of textiles increased more than ever and created the foundation of fashion as we know it today.

The birth of fast fashion

The term ‘fast fashion’ was coined in the 1990s by the New York Times. It referred to the mass production of cheap quality clothing.

Today, we see fast fashion almost everywhere. Half the things in your closet are a product of fast fashion.

In fact, today the fashion industry produces about 53 million tonnes of fibre every year, 70% of which ends up in garbage dumps, or is incinerated.

The digital revolution of the industry

The 20th century was hyper-focused on mass production. The aim was to produce more, fast but at a lower cost.

Computer and robotics marked the beginning of the 3rd industrial revolution. With technology like laser cutting and 3D printing, the design process has become completely automated.

The move to sustainable fashion – the current reality and future

The sustainable fashion movement is a direct product of fast fashion and an indirect result of climate change.

In the 2000s, people understood the harm that fast fashion was doing.

- Waste – According to the Environmental Protection Agency (EPA), 17 million tons of textile waste were generated in 2018, of which only 2.5 million tons were recycled.

- CO2 emissions – The Ellen MacArthur Foundation found that the fashion industry is responsible for 10% of global CO2 emissions each year.

- Water pollution – Cotton production is extremely water intensive. These textiles not only just take up a lot of water but also contribute to marine pollution.

These staggering numbers, led to many independent organizations coming forward with sustainable alternatives to fast fashion.

Hemp textile – today’s alternative for a better tomorrow

Among these alternatives, one is particularly favoured today and that is hemp textile. What made hemp textile so popular among people is that it checks most of the boxes of sustainable fabric.

- Hemp plants absorb CO2 faster from the environment as compared to other plants. A single acre of the plant can sequester over 9.82 tons of CO2 in its lifespan.

- The water requirements of hemp are significantly less than other fabrics. For example, cotton needs 9,758 litres of water for a 1-kilogram yield, hemp only needs 343 liters of water for the same yield.

- The main reason why all our clothes end up in landfills is that they are made with cheap quality materials. The corporations want you to buy more. Hemp, on the other hand, is a natural fabric that is more durable than most conventional fabrics. It even gets softer with each wash making it hard to part ways with a hemp shirt.

There was a time when clothing was a basic need. The reason why we wore clothes was simple – to shield ourselves from nature. However, over time clothing has become about everything but sustenance. We buy clothes as a status symbol, to express ourselves, for cultural distinctions, and more.

Result? The textile industry has become a glaring problem of the 21st century’s climate change.

While not buying clothes is not an option, we can always be conscious of the choices we make. For each garment we purchase, we need to think about all the resources that have gone into it. Limit your consumption, and when you do make a purchase, go for a sustainable alternative like hemp.

Sources:

https://www.statista.com/topics/5091/apparel-market-worldwide/#topicHeader__wrapper

https://hempfoundation.net/can-hemp-clothing-save-the-world-really-how/

https://www.treehugger.com/fast-fashion-environmental-ethical-issues-4869800

https://www.britannica.com/topic/textile/The-modern-textile-industry

https://www.thoughtco.com/textile-machinery-industrial-revolution-4076291

https://www.britannica.com/topic/wool