[vc_row][vc_column][vc_column_text]Hemp clothing manufacturing is a painstaking, yet fascinating process. Before we tell you more about it, let’s understand hemp.

Hemp is an eco-friendly crop that gives more to mother nature than it takes. The plant that grows wild and free avoids soil erosion as its deep roots grasp the soil firmly. It also purifies the soil by absorbing toxic materials without affecting the harvested crop. Hemp does not require pesticides to grow because of its a natural repellent.

Hemp sounds beyond amazing yet cotton still remains the most natural clothing choice. The cotton production in the U.S. during 2018-19 is at 3,999 metric tons. Manufacturing one cotton shirt takes 2,700 litres of water, to give you a perspective that is the amount an average human drinks in 2 and a half years. Hemp clothing consumes much lesser water with double the yield while compared to cotton.[/vc_column_text][vc_column_text]

Before we Delve into Hemp Clothing Manufacturing – Understand The History Of Hemp Clothing

The stalks of the hemp plant were harvested for the fibre that can be spun into thread and then clothing. Traces of hemp fabric dates back nearly 10,000 years with archeologists finding remnants in Iraq and China. In Iraq, hemp was spun into cloth around 8,000 BC while Europeans inculcated hemp in their lives by 1,200 BC.

Although hemp is a strain of the cannabis plant it only has 0.3% of THC. All those who thought they could roll up a hemp shirt to smoke are wrong, this strain is incapable of getting people high.

Yet, over the years, governments around the world made every strain of marijuana illegal but times are changing again. Climate change is our biggest problem at the moment and although we cannot stop living our everyday lives; it is our duty to do something about it.

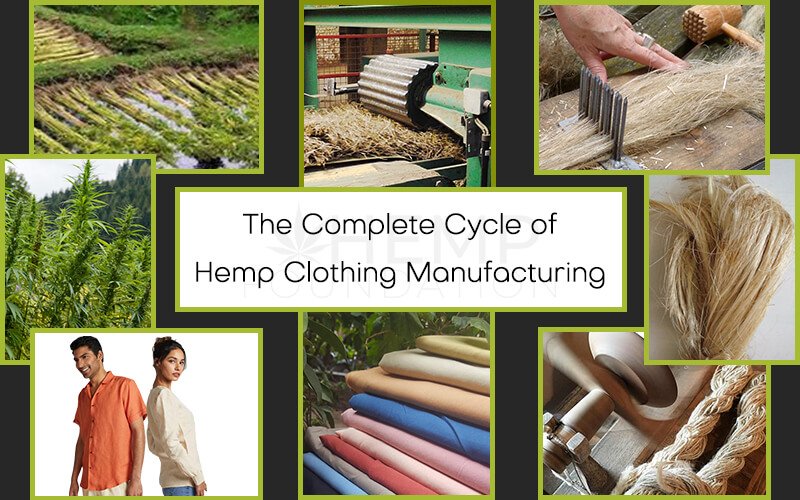

We all wear clothes, it has become a basic necessity for human life. Understanding how the hemp plant is a much better fabric solution than cotton requires us to grasp the complete cycle of manufacturing hemp clothing.[/vc_column_text][vc_column_text]

A Step By Step Guide Of Hemp Clothing Manufacturing

Hemp stalk has a cellulose fiber used to make shirts, dresses, hats, jeans, bags, canvas, ropes, etc. Founder of Ford Motor Company Henry Ford made a car partially out of hemp to assist the American hemp farmers. In America, 80% of clothing was manufactured from hemp until the 1920s when prohibition against the plant began.

Hemp can be manufactured into fabric organically and chemically. However, the point of using hemp is to reduce harm to the environment. The chemical method is faster and cheaper but needs to be monitored on the basis of damages caused to our ecosystem.

The organic method may be more tedious but the satisfaction of seeing it through organically is worth the time and effort. Here is the clear cut organic method of Hemp clothing manufacturing:[/vc_column_text][vc_column_text]

1. Retting:

This is the first process after harvesting the hemp crop and separating the stalks. Retting is the method of separating the long fibers from the plant to spin into yarn. There are three retting methods, Field, Water and Mechanical. Water retting is a bit riskier as the process will contaminate the water source.

However, field retting is allowing the crop to naturally dry which takes about 14 to 21 days depending on the weather. Water redding gives a higher quality and more uniform fiber but the wastewater needs to be treated at a sewage treatment plant to avoid pollution.

Mechanical retting is like it sounds, a machine is used to separate the fiber from the hurd. This is a much faster process of decaying the glue that sticks the fiber to the woody core of the hemp stalk.

2. Spinning and Weaving:

The next step is spinning the hemp fibers into a continuous yarn which is then woven into the fabric used for clothing. To organically spin hemp a specialized spinning machine is required. The available spinning machines are ideal for shorter fibers that come out of cotton or wool. Chemically processing hemp fibers produce shorter strands that can be spun with the readily available machine.

Although acquiring specialized machinery will be difficult, it is a worthwhile investment. Hemp processed organically allows the fiber to hold its absorption quality making the clothing much more durable than the chemical process product. Organic hemp clothing is also assured to keep the skin safe from UV rays.

3. Cleaning and Softening:

The hemp fabric can be a little stiff and is put through a cleaning and softening process to make the clothes wearable. Hemp has low lignin content meaning it can be pulped with less chemicals than wood.

The fabric does not need extremely toxic chemicals and can be cleaned with hydrogen peroxide rather than chlorine dioxide. This means no extremely toxic chemicals are dumped into the water stream.

Companies are exploring even more eco-friendly methods to manufacture hemp fabric. EVOLUTION is one such company that focuses on eco-friendly methods of production. It has pioneered many new methods to produce high-quality hemp garments.

4. Dyeing:

The final process of manufacturing hemp garments is dyeing the product. For an organic hemp product, low impact and fiber reactive dyes can be used. These dyes made from natural components have no heavy metal content and are water-soluble. Many might wonder why not use naturally made dyes. It is a common misconception that natural dyes are less harmful to the environment.

Natural dyes are made by a process of extracting the pigment molecules from plants, earth clays and sometimes even insects. However, the process requires the use of even more harmful chemicals than synthesized in a lab. Hence, the fiber reactive dye is used as it requires no on-site water filtration.

Hemp Clothing Is the Answer To Many Of Our Worldly Problems

The clothing made out of hemp is clearly more eco-friendly and durable than all the readily available textiles. Hemp clothing is also the answer to many concerns we face from chemical fibers to polluting the earth. Here are a few of the many problems hemp can solve.[/vc_column_text][vc_column_text]

Do you want to finally buy clothes that last longer than a year or two?

However, durability is the biggest problem in the clothing industry today. Hemp has antimicrobial properties making the fabric stronger and more durable than most. The clothes also keep their shape unlike cotton that eventually becomes distorted.

Are you tired or uncomfortable and color leaking clothes?

Well look no more, with hemp getting popular and legal you will never have to wear suffocating clothes again. The porous nature of hemp allows the fabric to trap heat in the winter and stay loose and breathable in summer. Clothes losing their color is an issue we all face but hemp’s porous nature retains the dye better than any other textile including cotton.

Do you feel a sense of duty to wear biodegradable clothes?

Hemp is a much more durable fabric but even if you do have to throw out your clothes, it is a 100% biodegradable. Other fabrics are not biodegradable and when disposed they just sit in the landfill for a very long time. Hemp clothing naturally degrades but is also durable making it an offer you cannot refuse.

After seeing all the good hemp fabric has to offer, one must wonder why our stores are still filled with wasteful materials like polyester and cotton. Clothing is a part of all our lives and shopping for clothes should be seen in a different light. We must ask ourselves if the clothing is good not just for us but the environment. In the case of hemp, the answer is always a yes, as it is one of the most eco-friendly plants in the world.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Reference Links:

Hemp Fiber – Eco Friendly Fabric

Hemp Clothing

FAQs about hemp fabric[/vc_column_text][/vc_column][/vc_row]