In 2021, 13.5 million hectares of cultivable land were used to grow cotton – in India alone, says this report by the leading analytics firm statista. That figure is not even semi-global in its coverage, yet it is scary to think about– and what’s more, it is expected to increase substantially by 2023. The question is that If Cotton & Polyester is so Bad Why There is No Other Alternative?

Couple that with the waste-heavy processes of production of the various polyester fabrics and we have a nice little recipe for planetary resource debt.

The cotton and polyester industries are not only saturated, they are also wasteful.

For example, in their report titled “Water – The Next Carbon?”, The World Wildlife Fund has estimated that it currently takes around 5,000 liters of water to produce a single cotton T-shirt.

There are numerous other problems with cotton and polyester that will be highlighted down the line in this article, but for now, suffice it to say that cotton and polyester are pretty taxing in multiple ways.

But if cotton and polyester are so bad, why are they still so popular? Why are they still the preference of billions of people globally? Why is there no sustainable product that can be used as an alternative to them?

These, and similar questions make up the content of this article, so without any further ado, let’s get right into the meat and potatoes of the article.

Upfront Conclusion: What Is The Alternative

Hemp, a plant that has been cultivated for millennia, may be just the solution to our dilemma. According to this study, published by McGill University, Canada, Hemp is one of the most sustainable plants for soil, giving back approximately 60% of the nutrients it takes.

Hemp is also one of the most sustainable fabrics that one can buy in the market today, not just because of the nature of the raw plant, but also because of the properties of the fabric.

| S. # | Property Of Hemp Fabric | Numbers |

| 1. | Stretchability | Medium (for fine threads) |

| 2. | Total Possible Thread Count | 400+ |

| 3. | Average Thread Count | 250 – 300 |

| 4. | Shrinkage | Low; pilling-resistant. |

| 5. | Breathability | Very High |

| 6. | Moisture Wicking Capabilities | Very High |

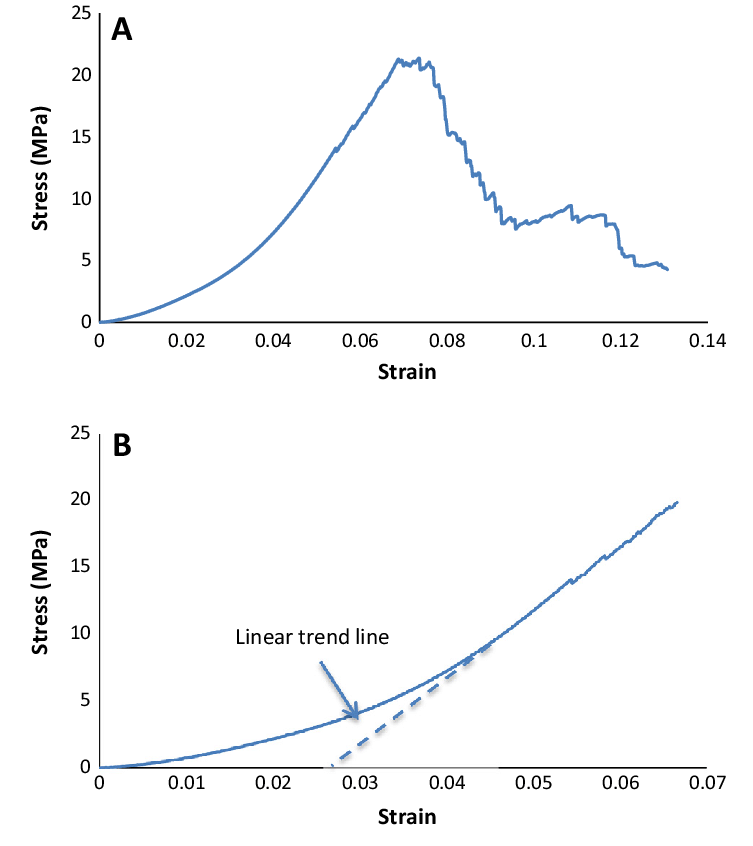

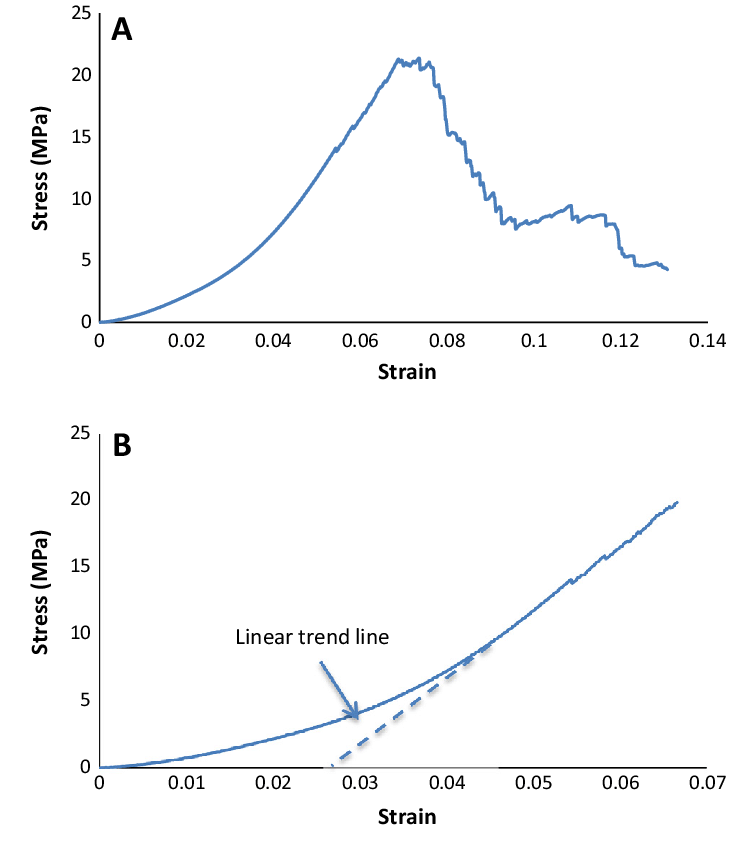

Image: A is the Complete Stress Curve of Hemp Fabrics: As you can see, it is highly durable.

Advantages of Hemp Fabric:

The advantages that hemp fabrics have over other textiles begin right from the pre-production process, and extend past the lifespan of the cloth.

- Hemp takes much less energy, labor, and water to plant, farm, harvest, and produce as compared to (pretty much) every single other textile.

- Hemp is a very rugged and hardy fabric, making it suitable for all types of cloths, and today hemp is finding popular uses right from clothing to household linen.

- Hemp fabrics are naturally pest-resistant as hemp fiber is made from the outer stalks of the sativa plant, and these stalks are great bug-repellants.

- Hemp fabrics are mold-resistant, extremely durable, and stronger than other fabrics that have similar textures, which is why hemp is becoming a popular choice for making pouches and heavy-duty transport sacks.

- Hemp fabric has a lot of antimicrobial properties as well – manufacturers have discovered that hemp fabrics retain a lot of their natural secondary metabolites, which keeps the bacterial and microbial counts within their fabrics low.

If the correct processes are used and are executed correctly, hemp fabric is almost texturally indistinguishable from the fan favorite, cotton, and is a very viable replacement for other fabrics too.

Image: B is the detail of the initial nonlinear part of the stress curve for hemp fabrics, showing high resistance.

The Polyester Production Process

Polyester is a smooth, water-repellent fabric that is synthesized from petroleum. It is made from strands of polymers woven together. These polymers are called polyethylene terephthalate synthetics or PET synthetics for short.

Think of it this way: at the very base level, polyester is basically a sheet of plastic that you can wear.

That is why you may have also heard the term “PET bottles” or”PET containers”, because they are also made from a very similar polymer.

The production of polyester products, of which synthesized fabrics are a big part, follows the following line:

- Polymerization: Ethylene Glycol is reacted with dimethyl terephthalate to produce a gooey material that moves down the line for further processing.

- Spinning: The gum is cut into small pellets, which are then put into a giant vat and heated to a liquid.

- Drawing And Winding: the liquid is then siphoned out into thin tube-like strings and woven into “ropes”. The polyester yarn is now ready to be woven into a fabric.

- Blending: [Optional] The polyester yarn can be mixed with other fabrics (like cotton or linen) to create blended fabrics.

The Cotton Production Process

Cotton and its derivatives are the most popular fabrics for clothes in the modern world, and most of the cotton used today comes from third-world countries.

Cotton is a plant that is sown in late autumn and harvested at the turn of spring. Cotton usually grows best in climates that are hot, and where the summers last longer than is normal for the rest of the world.

The basic production process that is followed to obtain cotton fabric has changed very little over the centuries, and it runs something like this:

- Sowing And Harvesting: The cotton is planted and the fluffy white spheres that encase the plants’ seeds (these are known as “bolls”) are harvested by machines called spindle pickers and stripper-harvesters.

- Ginning: After harvesting, we need to obtain cotton fibers, which is done by way of saw ginning or roller ginning. Roller gins “draw” the cotton through a roller that has teeth to separate the seeds and dirt, and saw gins pull the cotton through a mesh that acts as a sieve. The fibers are then compressed into bales.

- Spinning and Weaving: The compressed bales are then sorted by quality, bleached with hypochlorite or sometimes peroxide, and then spun into yarn. The yarn can then be woven into cloth for use.

Cotton And Polyester Disadvantages

Mass use aside, these two uber-popular fabrics have several demerits to their name, and these have been proven time and again with research. If cotton & Polyester is So Bad Why There is No Other Alternative?

The main disadvantages of cotton and polyester are:

- High Production Energy Cost: Polyester is basically wearable plastic, which means that it has extremely high energy requirements in order to be produced.

- Is Non-Biodegradable: Being petroleum-based, polyester does not degrade or decompose, just like plastic.

This will create a waste management crisis of epic proportions in a couple decades, given that half of all clothes currently produced contain polyester.

- Allergy Issues: Polyester fabrics (including polyester blends) are not hypoallergenic materials, which means that they can cause skin diseases and hormone issues.

- Water: Both cotton and polyester require an asinine amount of water to yield usable items, but cotton significantly more so than polyester, and this includes water required for plant growth.

- Poor Labour Standards: As was mentioned, these industries mainly depend on third-world countries for the raw materials required for production, where there are negligible (if any) labor laws. In fact, the fabric industry is a big source of modern slavery.

- Fabric Properties: Now that we’ve gotten the macro disadvantages out of the way, we come to the properties of the fabrics themselves.

For example, polyester fabrics are not breathable, they dont wick moisture away, they are hard to get stains out of, and they are annoying to iron and dry.

Cotton fabric too, has a shrinkage rate of anywhere between 4% to 10%, fades easily if proper dyes are not used, takes very long to dry because it retains water, and is a high(er) maintenance fabric on the whole.

That is why we ask If cotton & Polyester is So Bad Why There is No Other Alternative?

The Hemp Production Process

Hemp fabric is made from the long, supple strands of fiber that bind together to make up the stalk and stem of the plant. These fibers are separated from each other and then go through various products to become yarn or fabric rolls.

The Hemp fabric production process follows these lines:

- Cutting: The plants first need to be cut, and while small-scale enterprises cut the whole plant, commercial enterprises have machines that cut the Hemp plants four to five feet above the ground.

- Retting: this is the process of causing the pectin in the stalks to decay, which will naturally separate the fibers from the stalks of the plant.

Leaving the plants standing in the field will do the job naturally, although some companies use chemicals to speed up the process.

These chemically augmented hemp fabrics are usually labeled “Hemp Viscose”, so it is worth looking at the tags on fabrics.

- Breaking: This process is peeling the fibers away from the stalk, which is done by a machine called the decorticator, and this device can be used for other plants also.

- Scutching And Hackling: These two processes scutching (beating) and hackling (combing) remove any impurities from the hemp fibers, which can then be spun into threads.

- Spinning: There are two types of spinning: wet and dry; wherein wet spinning produces fine threads for things like clothing and linen, and dry spinning produces coarser yarns.

Why Are Hemp Fabrics Not More Popular

If cotton & Polyester is So Bad Why There is No Other Alternative? Hemp is the alternate. The main reason why hemp fabrics are not more popular is because of the social stigma that its source plant (cannabis sativa) carries with it. Despite the extremely low amounts of THC that cannabis sativa contains, people still assume that it is a drug, and club the plant with other narcotics, harming its reputation.

Other than that, there is also a significant lack of awareness on the part of the people; the majority of the population simply believes that cotton and polyester are must-use products that have these major disadvantages, but that there is no alternative to them at all.

This perception is now changing through brand efforts of companies that produce hemp, as their content is beginning to reach a wider audience.

Several brands have opened in-house online clothing stores in order to sell hemp clothing directly to customers, making hemp clothing more accessible to everyone.

Challenges Faced By Hemp Fabrics

The biggest issue to the growth of the hemp fabric industry is the fact that cannabis sativa, the raw plant from which hemp fabrics are most commonly made, has only been partially legalized all around the world.

This half-baked legalization imposes certain restrictions on the production process which can affect the supply of the fabric to customers, but fortunately this development has not hindered the demand for the textile too much.

Even in India, only industrial hemp has been legalized (in the hilly state of Uttarakhand), and the matter is not helped by the fact that one of the strains of cannabis sativa is used as a drug.

The reputation of hemp was hindered in the past because of the bond that the plant shares with its psychoactive cousin, but thankfully, because of growing awareness, this perception is changing.

In A Nutshell: Why Is Hemp The Better Choice?

Hemp is a plant that gives back to the environment, is quick and easy to produce, has had proven viable commercial deployment, matches quality expectations, and is a fabric that has many uses, both commercially and industrially.

Even most of the by-product runoff from the hemp production process (such as hemp hurds) can also be used, or at the very least, repurposed for other products. The challenges that hemp fabric faces can be summed up with the words “lack of awareness”, but even this is being dealt with by way of information and education on the part of hemp fabric brands. Hemp fabric is also beginning to be sold commercially through e-retail mediums that allow the customer to connect directly with the brand.

In the near future, we will see hemp fabrics take center-stage as an extremely sustainable, versatile, comfortable, fashionable fabric.

Now you got the answer of the Question that If cotton & Polyester is So Bad Why There is No Other Alternative?

Appendix

Sources:

- https://www.sustainably-chic.com/blog/what-is-polyester

- https://thefashionadvocate.com/blogs/news/four-ethical-and-sustainable-fabric-alternatives-to-polyester-fast-fashion

- https://oureverydaylife.com/how-to-iron-cotton-clothing-12272330.html

- https://sewguide.com/how-is-polyester-made/

- https://www.statista.com/statistics/765839/india-area-of-cultivation-for-cotton/

- https://oureverydaylife.com/how-is-cotton-made-12571047.html

- https://hempfoundation.net/hemp-vs-linen-similarities-and-differences/

- https://hempfoundation.net/hemp-fabrics/

- https://hempfoundation.net/hemp-vs-cotton-which-has-the-lowest-ecological-footprint/

- https://alsco.com/resources/polyester-cotton/

- https://www.britishmade.gifts/blogs/news/polyester-vs-cotton-the-pros-and-cons#:~:text=Cotton%20is%20typically%20more%20breathable%20that%20polyester%2C%20the,as%20cotton%2C%20as%20it%20isn%E2%80%99t%20a%20natural%20substance.

- https://www.daditextile.com/advantages-and-disadvantages-of-polyester-cotton-fabric.html

- https://silverbobbin.com/advantages-and-disadvantages-of-polyester/

- https://farmandanimals.com/how-much-water-does-it-take-to-grow-cotton/

- https://www.worldwildlife.org/blogs/sustainability-works/posts/water-the-next-carbon

- https://www.leftyproductionco.com/post/the-ethical-alternatives-to-polyester-fast-fashion

- https://eap.mcgill.ca/CPH_3.htm

- https://www.thebluntness.com/posts/benefits-of-hemp-fabric

- https://www.houseofu.com/en/blog/the-benefits-of-hemp-fabric/

- https://hempfoundation.net/how-hemp-fabrics-are-made/

- https://goodonyou.eco/material-guide-hemp/

- https://in.search.yahoo.com/search?fr=mcafee&type=E211IN885G0&p=usd+inr+2009

- https://www.prnewswire.com/in/news-releases/primary-reason-the-sustainable-hemp-textile-is-not-as-popular-as-it-should-be-853263342.html

- https://ghsindustries.com/15-advantages-disadvantages-of-hemp-fabric/#:~:text=One%20of%20the%20disadvantages%20of%20hemp%20fabric%20is,because%20there%20has%20been%20a%20lag%20in%20production.