Water Consumption of the Fashion Industry, At Different Stages? How cutting It Down can Impact the Lives of people

Water Footprint of the Fashion Industry and a Way to Reduce It

When buying clothes, people rarely think about the environmental toll it took to make that particular piece of clothing. But the impact of the fashion industry on the environment is a discussion worth having. Water consumption of the fashion & Textile industry has long been a cause for concern in a world where 2.7 billion people lack an adequate supply of water.

Water consumption of the fashion industry & Textile Industry.

Fast fashion relies heavily on the supply of fresh water for its survival. From the irrigation of cotton crops to the household washing of clothes, fashion is a thirsty industry.

It is currently the world’s second most water-intensive industry with annual water consumption of around 79 billion cubic meters.

How to reduce the fashion industry’s water footprint and pollution caused by textile production?

This article delves into the various stages of the fashion supply chain that contribute to water pollution, such as agricultural runoff and dyeing processes, and explores sustainable solutions to minimize this environmental impact.

Water Consumption of the Fashion Industry

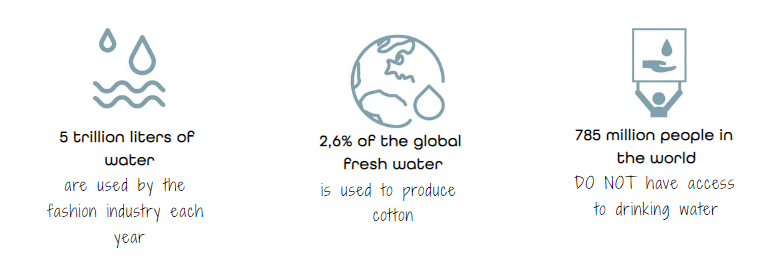

To start, here are a few facts that would effectively paint a picture of the extensive water consumption of the fashion industry. Water consumption of the fashion & textile industry is very high.

- Around 20,000 litres of water is needed to make one t-shirt and one pair of jeans (That is enough drinking water for a single person for 900 days).

- Conventional cotton t-shirt needs 2,494 litres of water to make.

- It takes around 17,128 litres of water to make a cow skin leather tote bag

- A pair of cow skin leather boots requires 12,370 litres of water.

- It takes 7,612 litres of water to make a pair of cow-skin leather shoes.

How can that much water possibly be used in fashion?

To answer that, you need to look at the entire supply chain of fast fashion products. Here, we will talk about the usage of water in the textile industry to give you a better understanding.

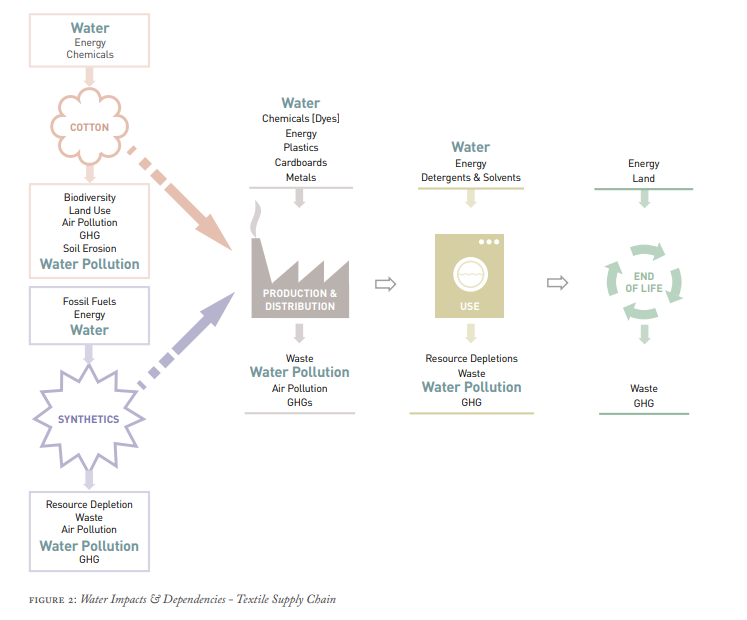

Water Impacts and Dependencies

Textile and clothing production uses and pollutes a massive amount of water across the supply chain. Both surface water and groundwater is used to feed this industry. This contributes to freshwater depletion, especially in water-stressed regions.

On the other hand, increasing pollution leads to eutrophication. It is a process that causes algal blooms, dead zones, and fish kills to occur in a body of water. Needless to say, fashion contaminates drinking water sources and has a devastating impact on aquatic life.

The most critical water impacts and dependencies in textile and clothing manufacturing occur at the following stages of the supply chain:

- Cotton growing

- Textile production (which includes dyeing, finishing, and treating)

- Consumer laundering

This image perfectly illustrates the water impacts and dependencies across the supply chain, and its broader environmental impact.

Cotton – A Thirsty Crop

Cotton and polyester are the two most dominant fibres used in the textile and apparel manufacturing industry by market volume.

On average, cotton makes up around 35% to 40% of textile production. And it also contributes to the massive water consumption of cotton fashion industry.

Growing cotton accounts for around 69% of the water footprint of the textile industry. It takes as much as 10,000 to 20,000 litres of water to produce just one kilogram of raw cotton.

Cotton is the second most produced fibre in the world, and the majority of cotton is cultivated in countries that are already experiencing severe water stress.

The irrigation required for cotton crops puts stress on the local water supply and depletes aquifers and groundwater supplies. These natural resources take thousands of years to replenish.

It doesn’t end there.

Once the raw cotton is harvested, it needs to be spun, dyed, and finished before it can be used to make apparel. This processing requires around 100 to 150 litres of water for each kilogram of cotton fibre.

Cotton cultivation and processing also play a huge role in polluting the world’s water sources.

Cotton production accounts for around 16% of all insecticides sold around the world. That and all the chemicals used in cotton processing often end up back in the water.

Water Consumption in Various Stages: Dyeing, Finishing, and Processing

Conventional methods of wet processing and textile dyeing require massive amounts of freshwater withdrawal and wastewater disposal.

Dye houses in China, India, and Bangladesh have a well-documented track record of exhausting local water supplies and polluting local rivers and streams with wastewater.

The apparel industry uses over 5 trillion liters of water every year to dye around 28 billion kilograms of textiles. Water consumption of the fashion & textile industry is very high.

The figure is so staggering that it’s hard to put into perspective. But there’s more!

Apart from dyeing, water is also used as a solvent in various pre-treatment and finishing processes, which include things like washing, bleaching, and scouring.

Impact of the Fashion Industry on Water Pollution

You cannot talk about the water consumption of the fashion industry without mentioning the role this sector plays in water pollution.

Fashion industry water pollution occurs at various stages of the supply chain – from cotton cultivation to fibers and textile processing and apparel manufacturing.

Cotton cultivation accounts for 4% of artificial phosphorus and nitrogen fertilizers used around the world. Estimates suggest that growing cotton requires around 8 million tons of synthetic fertilizers and 200,000 tons of pesticides every year.

The processing of fibre and textiles also pollutes water. Around 8,000 synthetic chemicals are used for turning raw materials into textiles.

Textile treatment and dyeing account for approximately 20% of the world’s industrial water pollution.

Another way fast fashion pollutes water is through microfibers.

Many synthetic fabrics such as nylon and polyester are made from plastic. When these fabrics break down, they form “microfibers” that spread through the natural environment.

The plastic-based fabrics such as nylon and polyester produce microfibers when the clothes are washed. These microfibers are essentially microplastics that do not degrade over time.

Laundry water contains a significant amount of microfibers, which ultimately end up in the ocean.

Studies show that 35% of the microplastics found in the ocean come from washing clothes that are made of synthetic fabrics.

Industrial Hemp Can Help Solve the Fashion Industry’s Water Challenge

While the world has long been aware of the devastating impact of fast fashion on the environment, little has been done to fix the problem.

Cotton continues to dominate the textile industry, and it is still one of the most cultivated crops in the world.

The first step towards fixing fashion’s water problem is to eliminate (or at least reduce) cotton dependency.

Think about it; what if there was a crop that requires MUCH less water and less harmful pesticides to grow? And what if that crop could be used to create a fabric that is just as good as cotton?

The name of that wonderful plant is industrial hemp!

Industrial hemp is the “sober cousin” of marijuana.

It is a species of Cannabis Sativa with significantly less THC content. That means industrial hemp CANNOT get you high.

But it has several excellent uses. Hemp fibre has been used throughout history for making fabrics, ropes, and other industrial materials.

Today, hemp fibre can be used to make biodegradable and eco-friendly fabric that can replace cotton.

Let’s look at a few ways hemp is a more sustainable crop than cotton:

Hemp Uses Much Less Water than Cotton:

Unlike cotton, hemp is environmentally friendly. It uses 50% less water per season than cotton. It requires very little irrigation and can be grown in regions where water sources are scarce.

Over half of the world’s cotton plantations rely on irrigation because the crop is grown in relatively dry regions such as Egypt, California, Texas, and China’s Xinjiang province.

Furthermore, cotton processing requires four times as much water as hemp does. Studies have shown that industrial hemp is some of the least water-intensive crops out there.

Hemp Nourishes the Soil:

While cotton cultivation has damaging impacts on the soil, hemp offers nourishment to the soil it grows on. While the bark of the hemp stalk is used for making fibre, the leftover hurds and leaves can be used as fertilizer. That makes hemp an excellent rotational crop.

Furthermore, hemp cultivation requires half the amount of land required to grow cotton. It also yields 3 times more fibre than cotton. Industrial hemp is also known to absorb more CO2 from the environment than trees.

Hemp Doesn’t Need Pesticides:

While cotton requires a large number of pesticides and artificial fertilizers to grow, hemp doesn’t.

Hemp can be grown without agricultural chemicals such as pesticides, fungicides, and herbicides. Being a hardy plant, hemp is naturally resistant to most pests.

The leafy plants tend to grow tall. Since they are planted close together, the plants create a dense canopy, which blocks out the sun and prevents weed growth.

Hemp Fabric is Stronger and More Durable than Cotton:

Hemp fibre can be used to create high-quality and breathable fabrics that are antibacterial and moisture-absorbent.

Clothes made of hemp fabric tend to be soft and comfortable. The fabric ages beautifully and becomes more comfortable over time.

Hemp clothing becomes softer with each wash but does not lose its durability or strength. So, you don’t need to worry about ruining your favourite clothes with frequent washing.

There are many incredible benefits of using hemp as an alternative to cotton.

Wrapping Up: It’s Time We Hold Fast Fashion Accountable and Course Correct

The extremely high water consumption of the fashion industry has a long-term damaging impact on the environment. Considering that billions of people worldwide suffer because of the lack of water, it is time we hold fast fashion accountable.

While it’s necessary to make long-term changes in the fashion industry as a whole, we can start by addressing the root of the problem. Reducing cotton dependency and cultivation is a great place to start.

In the debate of “what is better: cotton or hemp,” hemp is the clear winner. It’s about time the world catches on to the many benefits and uses of industrial hemp and uses it as a viable alternative to cotton.