How the Auto Industry Uses Hemp Plastic

In 1941, Henry Ford built a ‘Hemp Car’. It was the first known hemp plastic automotive innovation. However, it was only partially made of hemp (about 7%) and never hit mass production.

Yet it was a revolutionary idea. A car that was lighter, stronger, and partly biodegradable. Fast forward to 2016, Canadian company Renew Sports Cars showcased the first car made almost entirely from hemp.

Source: AutoEvolution

With that, hemp can, in theory, replace lots of conventional plastics and (and some metals) in automobiles.

This brings us to an important question: If we have working hemp car models, why aren’t they on the road today? Well, that’s because the use of hemp in the automotive industry faces technical, financial, and regulatory hurdles.

In this blog, we’ll explore the story of hemp in cars:

- What advantages it offers beyond being eco-friendly

- Who is already using hemp plastic car parts

- The challenges slowing mass adoption

- What it will take to shift gears toward a greener automotive future

Why Does the Use of Hemp in the Automotive Industry Make Sense?

The automotive industry is a significant contributor to global plastic pollution. In 2022 alone, the European automotive sector generated 1.6 million tonnes of plastic waste. Less than 19% of it was recycled.

Enter hemp. A material that offers environmental benefits and technical advantages.

- Yes, hemp breaks down naturally and has less of an effect on the environment over time.

- Of course, growing hemp sequesters CO2.

- And yes, hemp-based composites can replace petroleum-based plastics, reducing dependence on fossil fuels.

But hemp has perks that go beyond being environmentally friendly. Here are five more reasons to use hemp plastic in cars:

Lightweight Strength

Hemp fibers are very strong but also really light. When combined into composites, they can be as strong (or even stronger) than fiberglass, while making the part 30–40% lighter. That means cars weigh less, use less fuel, and produce lower emissions.

Thermal Resistance

Hemp-based composites tolerate heat and cold well. Car components like dashboards, door panels, and under-the-hood covers remain stable in high temperatures. This reduces warping or deformation.

Durability and Impact Resistance

Hemp fibers absorb shocks and distribute stress effectively. This makes panels and trims resistant to cracks or breakage during minor collisions.

Acoustic Insulation

Hemp fibers naturally absorb sound and vibrations. So hemp in car interiors makes rides quieter, reduces rattling, and cuts down on road noise, which improves overall comfort.

Biodegradability and Safety

Hemp composites break down naturally over time, unlike regular plastics, leaving very little waste behind. They’re also safer and less toxic if disposed of, making them a much cleaner choice for the environment after end of life.

These advantages show that automotive hemp plastic use isn’t just a green experiment. It improves car efficiency and safety too. The best part? Many automotive companies are already tapping into these benefits.

Who’s Already Banking on The Benefits of Hemp Plastic in the Automotive Industry

Cars made of hemp alone are yet to grace the markets. But many automakers are already incorporating hemp plastic car parts into their vehicles. These applications demonstrate that automotive hemp plastic use is not just theoretical. It’s real. And it is growing.

Here are some notable examples from across the globe:

- BMW – The i3 and i8 models use hemp fibers in door panels and dashboard trims. BMW has found that hemp composites reduce vehicle weight without compromising strength.

- Mercedes-Benz – A-Class and C-Class models feature interior components reinforced with hemp. These include the trunk liners and seat backs. These materials improve acoustic insulation and reduce vibration.

- Lotus Eco Elise – Lotus uses hemp composites for panels and body sections. This offers the benefit of lightweight strength and enhanced crash resilience.

These examples show that hemp plastic automotive applications are already solving real problems.

At the Hemp Foundation, we are well-equipped to supply hemp bioplastic to the automotive industry manufacturers, helping scale production and R&D globally.

Source: Hemp Foundation

So Why Don’t We Have Hemp Cars on the Road Yet?

We’ve seen that hemp plastic automotive materials work well in prototypes and some car parts. But full hemp cars are still mostly a dream. Why? It comes down to a few key issues:

Technical challenges

Hemp composites are strong and light, but making them consistent on a large scale is tricky. Fiber quality, resin bonding, and moisture levels can vary, which affects strength, heat resistance, and durability. Cars have strict safety standards, so everything needs to be tested carefully.

Financial barriers

Hemp growing and processing isn’t fully industrial yet. Supply chains are limited, production volumes are low, and costs are higher than regular plastics. Until we scale up, mass adoption will be expensive.

Policy and regulations

Hemp is tightly regulated in many countries. Without clear rules and certifications, car makers hesitate to use it widely. Dealing with legal frameworks also adds extra cost and time.

Consumer perception

Many people don’t know about the benefits of hemp plastic car parts, or they think of hemp as “just an alternative” material. Convincing buyers of its safety and durability is another hurdle.

Infrastructure limits

There aren’t enough industrial facilities to process hemp fibers and make composites at scale. This bottleneck slows down mainstream use.

In short, these challenges explain why we don’t see hemp cars in showrooms yet. Solving them will need better tech, supportive policies, more awareness, and scaled-up supply chains.

What We Need to Change Gears on Use of Hemp in Automotive

Now that we’ve seen the benefits and challenges of automotive hemp plastic use, it’s clear that moving forward will take effort from many sides.

- Car makers need to put more focus on research and development for hemp composites.

- People need to understand why hemp plastic car parts are useful because awareness creates demand.

- Suppliers should expand hemp production and processing, which will bring costs down and make materials easier to get.

- Governments should set clear rules for growing and using hemp, and offer incentives like tax breaks or grants for eco-friendly materials.

Most importantly, consumers need to up the demand for eco-friendly cars. After all, that’s the most compelling factor that will push automakers to innovate.

With the right momentum, automotive hemp plastic use will not just be a niche experiment. It will go mainstream. And the result? Reduced plastic pollution, lower vehicle weight, and greener cars overall.

FAQs

1. What makes hemp plastic automotive materials different from regular plastics?

Hemp composites are biodegradable, lightweight, and strong. So, unlike petroleum-based plastics, they reduce carbon footprint.

2. Can parts made of hemp plastic be used instead of metal or fiberglass ones?

Yes, hemp composites can be used to make dashboards, door panels, trunk covers, and seat backs. These auto parts are traditionally made from metal or fiberglass.

3. Is using hemp plastic in the automotive industry cost-effective?

Hemp prices are higher now because supply lines are limited. But as demand grows, the cost of hemp plastic in cars is likely to go down.

4. How are hemp car interiors made?

Hemp fibers are combined with resins to form composites. These are then molded into dashboards, door panels, and trims. This process creates hemp car interiors that are durable, lightweight, and eco-friendly.

Vishal Vivek

Vishal Vivek is the Founder and CEO of Ukhi, a pioneering bio-materials company dedicated to ending plastic pollution by converting agricultural waste into high-performance compostable polymers. With a background in sustainable entrepreneurship and over a decade of technology experience, he leads Ukhi’s vision to create scalable, planet-positive material solutions. Previously, Vishal founded the Hemp Foundation, where he empowered more than 1,000 farmers and advanced sustainable livelihood initiatives. His work has been recognized through awards such as the HDFC Parivartan Grant and featured in leading publications like Forbes and Entrepreneur. Times Group recognized him as a legendary entrepreneur and published his biography in “I Did IT- Vol 2” alongside social pioneers like Bindeshwar Pathak (Sulabh International) and Anshu Gupta (Goonj). Vishal has authored more than 200 articles on sustainability and hemp, reflecting his deep expertise and advocacy for regenerative solutions. His commitment to grassroots impact led him to live in the remote mountains of Uttarakhand, where he immersed himself in the lives of marginal farmers, understanding their challenges and co-creating economic opportunities through hemp-based initiatives. A deeply passionate innovator, Vishal often draws inspiration from seemingly impossible achievements: “If Elon Musk can make rockets reusable, or Dashrath Manjhi can carve a path through a mountain with rudimentary tools, why can’t we eliminate the demon of single-use plastic while uplifting struggling farmers? We will make it happen—whatever it takes.” Ukhi is proud to be supported by premier institutions including IIT Guwahati, NSRCEL-IIM Bangalore, Indian School of Business (Hyderabad), Indian Council of Agricultural Research (ICAR Pusa), and the Indian Institute of Packaging. Vishal is committed to demonstrating that business can be a powerful catalyst for global environmental and social good. Connect with Vishal Vivek

Related Posts

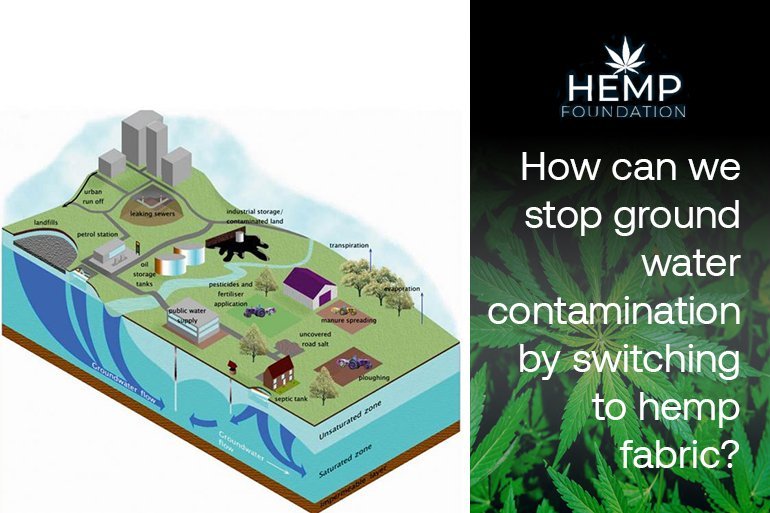

Impact of Hemp on Water Conservation and Climate Resilience

In this blog, we will delve deep into the role of hemp in water conservation initiatives, and the mu

Recycled Polyester vs. Recycled Cotton vs Hemp: Who Wins The Sustainability Race?

Recycled Polyester Vs. Recycled Cotton Vs Hemp: What’s Most Sustainable? So, you’re finally jump