How Hemp Fabrics Are Made

Before we tell you how to make hemp fabric, let’s showcase a bit of hemp’s history.

Hemp for Victory. That is a black and white movie directed by Raymond Evans and produced by the U.S. Department of Agriculture (USDA) in 1942. The film urges American farmers to grow to help in the U.S. war efforts. The Second World War, that is.

Earlier in 1937, the Marihuana Tax Act had been the first step towards criminalizing hemp, the botanical cousin of the narcotic cannabis or marijuana that has no psychoactive properties of its own. But that Act was relaxed when the U.S. joined the war.

Because the U.S. government desperately required hemp fabric as the Japanese had seen to it that the U.S. had no access to hemp imported from overseas. So, what was hemp required for? The fabric derived from it, as it happens.

Rowan Robinson mentions in his The Great Book of Hemp: The Complete Guide to the Environmental, Commercial. and Medicinal Uses of the World’s Most Extraordinary Plant (1996, Rochester, Vermont: Park Street Press) that every U.S. battleship needed 34,000 feet of rope made from hemp fabric.

However, ropes certainly are not the only product made from hemp fabric. Hemp textile has been in use as clothing for humans since ancient times, with China presenting the most continuous recorded history. There are different qualities of hemp fabric for varied uses.

What the Hemp Textile Market Looks Like?

A global report published by Fior Markets, a market research agency based in India, mentions that the cumulative annual growth rate (CAGR) for hemp products will be 16.2% between 2019 and 2026. The total value is estimated to reach US$14.67 billion by 2026.

The report categorizes hemp products into seeds, shives, and fibers. In the application sector of hemp fibers, hemp textile dominated in 2018 with a market share of 23.40%. The range of products made from hemp fibers encompasses a wide spectrum from ropes and twines to denim and fine textiles.

Incredible Though It May Seem

Who doesn’t know of Levi’s jeans? But hardly anyone knows that Levi Strauss fashioned his first pair of jeans from hemp fabric to lift it from the restrictions of being used as an industrial fiber only.

The yellowish-grey to dark brown hemp fibers soon became popular in the textile world, till it got banned in many countries across the globe due to human fallibility. With the prohibition being lifted in many countries, hemp textile is ruling again.

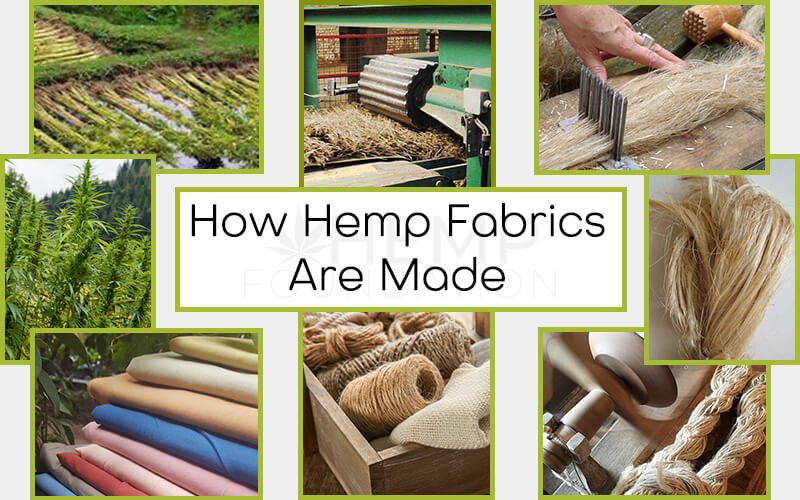

How to make hemp fabric

Apparently, making fabric from hemp is a simple four-step process: cultivate hemp, break it down, extract the fibers, and spin the fibers to produce textiles. But it really is a long-drawn and labor-intensive process where you need to be careful right from the stage of sowing the seeds.

Growing Hemp for Fibers

The cultivation patterns of hemp fibers and hemp for seeds are different, though they are the same plant. When cultivating the plant for fiber use, the seeds are sown close together: up to about 300,000 plants per acre, in comparison to a maximum of about 150,000 plants per acre for seeds.

That needs 30-55 pounds of seeds per acre and the rate of panting is 15-30 plants per square foot. Denser planting results in taller plants with virtually no branches, which increases the fiber yield. However, these are the standards in the U.S.

Europe does not cultivate more than 182,000 plants per acre. The fiber they get produces finer quality fabric. Grain drills used for wheat farming are usable for hemp planting. If air planters are used, the fan speed should be low as the seeds can break otherwise.

The depth at which seeds need to be planted averages between half to one inch. The drier the soil, the deeper should be the planting. It takes about five days for the seeds to emerge as sprouts when planted in spring.

Dense planting takes care of weeds and hemp is naturally pest resistant. Harvesting of hemp plants for fibers happens when the lower leaves of the female plants begin to become yellow. That is usually between early and middle flowering stages.

Cutting and Retting

It is technically possible to cut the plants with a sickle, but that is hardly the method used for large-scale commercial crops. The hemp harvester is a machine specifically designed for this plant. the critical point is to run the cutter bars four to five feet above the ground.

Then you cut and bale the hemp stalks and leave them in the field for about five weeks for retting. There are machines that cut and bale the stocks at one go. However, retting is an important process to separate the fibers.

Retting is the process to cause the pectin to decay so that the fiber separates from the non-fiber parts of the stem. Leaving the stalks in the field is the most natural process of retting as dew and natural bacteria and fungi do the job.

Some farmers soak the stems in water for retting. Some use chemicals like enzymes for hastening the process of retting. Whatever the process, it is important to make sure that the stalks are thoroughly dry before you take them to the next stage.

Breaking

Breaking is simply separating the dried hemp fibers from the hurds or the shives, the wooden core of the stems. It used to be a painful manual process before, but now a machine called the decorticator has made this process much simpler.

To decorticate is to peel the surface layer out and the decorticator is a machine for separating other plant fibers also.

Scutching

This is a process of beating the stems after breaking the fibers to separate the last of the woody cores from the fibers. This is really the final step in the separation process to scrape out the last of unwanted materials.

Hemp hurds have their own use, of course. But in the process of fiber extraction, they are an impurity that must be removed.

Hackling

This is the process of combing the stems for removing impurities that may yet cling to them. The hackling (or heckling) comb separates the line fibers from the tow fibers. Hackling combs make the line fibers straight and clean. It is customary to then card line fibers to size before baling them for spinning.

The tow fibers are just simply baled for use in producing coarse yarn, pulp, and staffing. Linen fibers are then spun for use as fine textiles in the apparel industry.

Source:i.ytimg.com

Roving

The ultimate step before putting hemp fibers on the spinning bobbins is known as roving. It is a process of twisting and drawing out the line fibers further to make hemp fiber stronger.

Spinning

There are two processes of spinning hemp fibers: wet and dry. Wet spinning uses water to produce finer yarns suitable for a variety of clothing. Dry spinning is usually reserved for tow fibers and leftover line fibers for producing coarser yarns.

Coarser yarns get used for making carpets, bags, shoes, etc. Finer yarns are made into clothing that feels like linen on the skin. Hemp textile makes truly comfortable summer wear for their high breathability.

Source:i.etsystatic.com

Now you know how to make hemp fabric.

Why Support Hemp Fabrics

Knowing how to make hemp fabric isn’t enough; you need to understand the global narrative around hemp as an environment-friendly crop. Hemp fabrics completely block UV rays so that your skin stays protected against these cancer-causing rays. Without making you sweat, because the fabric is so breathable.

Hemp also needs much less water than cotton, yields more fabric, and needs no pesticides. In addition, hemp helps top-soil preservation. Remnant leaves and flowers make the soil more fertile.

Sources:

The Great Book of Hemp: The Complete Guide to the Environmental, Commercial…