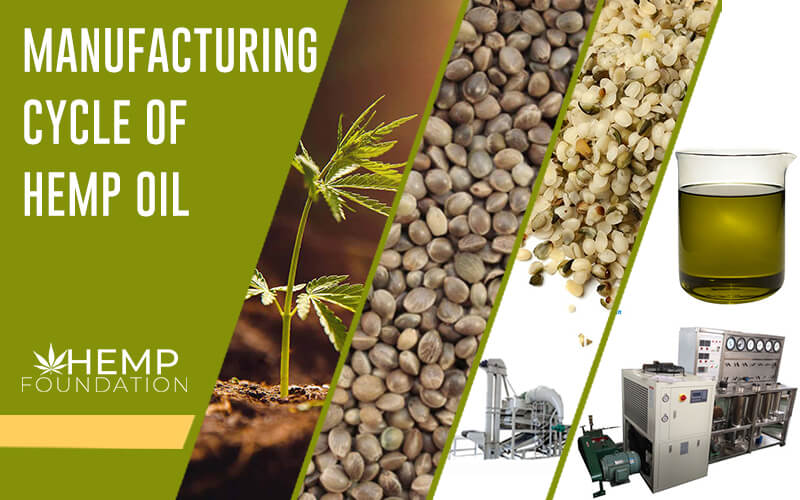

The Complete Cycle of Hemp Oil Manufacturing

[vc_row][vc_column][vc_column_text]Before we go into hemp oil manufacturing, let’s set a background.

The versatile hemp plant, or industrial hemp as it is also called, has been a part of human life since about 10,000 years ago. Then, in the 20th century, this plant simply disappeared from human use (except at the subterranean level maybe) and public discourse. A Himalayan blunder is the root cause of that.

Hemp was marked contraband by many other countries across the globe. Because hemp is a botanical cousin of the drug cannabis or marijuana since it belongs to the same plant species: Cannabis Sativa.

The blunder lies in overlooking a critical difference between the two. Cannabis has psychoactive properties, but hemp does not. The difference in the chemical composition of the two plants is the reason behind this.

Tetrahydrocannabinol (THC) is the compound with psychoactive properties. The presence of THC in cannabis varies from 7.5 to 10 percent, or higher. Its presence in hemp is limited to 0.3 percent or lower. That’s why cannabis can give you a high, but hemp cannot.

Hemp oil is completely different from cannabis oil or marijuana oil and has no mind-altering capacity. Hemp oil use will not make you fail a drug test.[/vc_column_text][vc_column_text]

Decoding Hemp Oil

The term hemp oil is a little confusing, for it can mean either of the two types of oil derived from the hemp plant: hemp seed oil and CBD oil. Oil derived from the seeds of the hemp plant is the edible hemp seed oil with amazing nutritional benefits. Hemp oil usually refers to hemp seed oil.

The oil derived from the flowers, leaves, and stems of hemp – rich in cannabidiol (CBD) – also has health benefits. It is commonly known as CBD oil. However, the terms “hemp CBD oil” or “hemp oil” are also used. For this article, hemp oil means hemp seed oil.

Unrefined hemp seed oil is dark green in color with a nutty taste and a grassy flavor. However, after some hours of extraction, the darker and thicker part subsides to the bottom of the container. The top layer then looks lighter green.

Refined hemp seed oil is almost colorless and has no flavor. Cold-pressed organic hemp seed oil is the most nutritious as it retains most of the nutrients present in the seeds. Some of the defining characteristics of hemp seed oil are:

- Hemp seed oil is rich in polyunsaturated fatty acids (PUFAs) necessary for human health. It has a remarkably low content of the bad fats and contains no cholesterol.

- The presence of omega 3 and omega 6 fatty acids in hemp seed oil corresponds to the exact proportions ideal for human health: three portions of omega 6 to one portion of omega 3.

Hemp seed oil is one of the most complete plant-based protein sources as it contains all 10 amino acids that the human body needs.[/vc_column_text][vc_column_text]

Hemp Oil Manufacturing

The hemp seed oil has several industrial uses, in addition to being a nutritious dietary supplement with amazing health benefits. There are several processes of extracting oil from hemp seeds. The process of extraction often depends on the intended use.

Step 1: Cleaning the Seeds

Threshing and winnowing the seeds manually or mechanically is highly important to ensure that no plant matter sticks to the seeds. The presence of plant matter can alter the chemical composition of the oil.

Step 2: Extracting the Oil

The extraction process can cause differences in the physical and chemical composition of the oil derived. Differences in the extraction process also lead to variations in the economics of the yield.[/vc_column_text][vc_column_text]

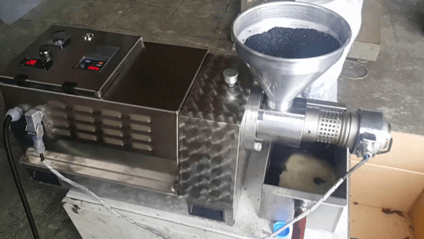

The Traditional Oilseed Press Machine Used in Hemp Oil Manufacturing

The traditional method of extracting oil from any seeds, including hemp seeds, involves the oilseed press machine. The more technical name for this machine is the expeller screw press. These machines come in two types: a continuous screw press and an interrupted screw press, usually with a resistor teeth.

The basic process is simple: the raw materials, in this case, hemp seeds, are dispensed on the seed hopper. The expeller screw presses the oil out of it, which then flows through canals that separate the pulp from the oil.

This age-old method of extracting oil from seeds and nuts yields the purest form of oil possible. It is known as cold pressing as the oil gets extracted at comparatively low temperatures: not higher than 120 degrees Fahrenheit (48.49 degrees Celsius). However, the process is not as simple as it sounds.

The moisture level of the seeds, or the nuts as in the case of hemp seeds, has to be just right. Improper storage leading to too high or too low moisture levels cause problems in the pressing.

Too much moisture in the seeds makes the oil to bind with the water so that extraction is difficult. If the seeds are too dry, then harder pressing is necessary, which may result in crossing the cold-pressing temperature threshold.[/vc_column_text][vc_column_text]

A traditional oil press machine

Source: i.ytimg.com

In fact, one of the issues with expeller screw machines is that they can get overheated when pressing harder seeds or nuts. Some companies use coolants to deal with this problem. The quality of seeds also affects the quality of the oil extracted and so does the actual pressing method.

Different types of screws are necessary for different seeds and nuts. A mistake there will affect the operation. Adjusting the distance between the press head and the screw end is another important factor. The tip size, the speed – all of these need to be just right.

In a nutshell, an experienced operator is critical to maintain the quality of the oil produced in the cold-press method.

A hand-crank machine

Source: alibaba.com

[/vc_column_text][vc_column_text]In case you want to make sure that you have the best quality hemp seed oil, you can always use a hand-crank machine and extract the oil at home. But it is hard work! However, if you do press the oil at home, don’t throw away the pulp.

The best thing is to use it in some foodstuffs. If you don’t quite feel up to that, feed it to birds, or use it as manure for your plants. The birds and/or the plants will be happy with your generosity![/vc_column_text][vc_column_text]

Adding CO2 to Extract Remnant Oil

Cold-pressing may be the most healthy, but it is definitely not the most efficient. Some oil remains in the pulp, which means the economics of oil per yield suffers. A recent (January 2015) article in the Chemical and Biochemical Quarterly reports on an experiment to optimize the oil yield through cold-pressing.

According to this experiment, the conditions that optimize oil yield through the expeller screw press method are:

- A temperature of 60 degrees Celsius (140 degrees Fahrenheit), which is beyond the cold-press threshold

- A frequency of 20 Hz

- A nozzle size of ID 6mm

To extract the remnant oil from the seedcake, the experimenters used a newly designed machine and used supercritical CO2 as a solvent. Supercritical CO2 is the liquid state of carbon dioxide held above its critical temperature and pressure points. This addition resulted in the last drop of oil getting extracted.

Five Industrial Processes of Extraction in Hemp Oil Manufacturing

A January 2019 article in the Journal of Cleaner Production reports on an experiment conducted in the Indian Institute of Technology, Roorkee, India. The purpose of this experiment was to identify the most economical method of hemp seed oil extraction for industrial use.

The experimenters also checked the physical and chemical properties. The processes compared were percolation, pyrolysis, superficial fluid extraction (SFE), sonication, and Soxhlet. The results indicate that SFE is the most economical method, followed by the soxhlet technique.[/vc_column_text][vc_column_text]

Final Say

For dietary purposes, nothing beats the goodness of the cold-press method.[/vc_column_text][vc_column_text]

Sources:

Making Hemp Seed Oil: A Simple Guide To How It’s Made

Cold Pressing and Supercritical CO2 Extraction of Hemp Cannabis sativa Seed Oil

Comparative study of different extraction processes for hemp (Cannabis sativa) seed oil considering physical, chemical and industrial-scale economic aspects[/vc_column_text][/vc_column][/vc_row]