Hemp Yarn

We can Make a Difference, Let's Start Now

What if we told you a simple yarn can change lives and heal the planet?

That’s exactly what hemp yarn does.

Here in the Himalayan villages of Uttarakhand, life hasn’t been easy for many. Families have been torn apart as men migrate to cities in the search of jobs. Women are left behind to shoulder the weight of empty farms and fading traditions.

But here’s the thing—hemp yarn is giving them a way to reclaim their lives.

Hemp is a miracle fiber. It’s natural, organic, and as sustainable as it gets. It uses less water, regenerates the soil, and even absorbs more carbon dioxide than trees.

For those of us who care about the planet (and I know you do!), it’s completely compostable.

But beyond its environmental benefits, hemp yarn is strong, versatile, and antibacterial. And every strand you use comes with a story. The story of women in remote villages weaving their strength, love, and resilience into every inch of yarn.

So, when you choose our hemp yarn, you’re making a difference. You’re helping bring livelihoods back to the mountains. And you are creating a more sustainable future, one thread at a time.

From Soil to Shop: How our Himalayan Hemp Yarn is Made

The Hemp Foundation hemp yarn comes from the heart of the Himalayas – from the mineral-rich soil and pure air. The hemp is grown using traditional organic farming techniques passed down through generations.

Here’s how we turn those plants into beautiful, high-quality yarn that you get home delivered:

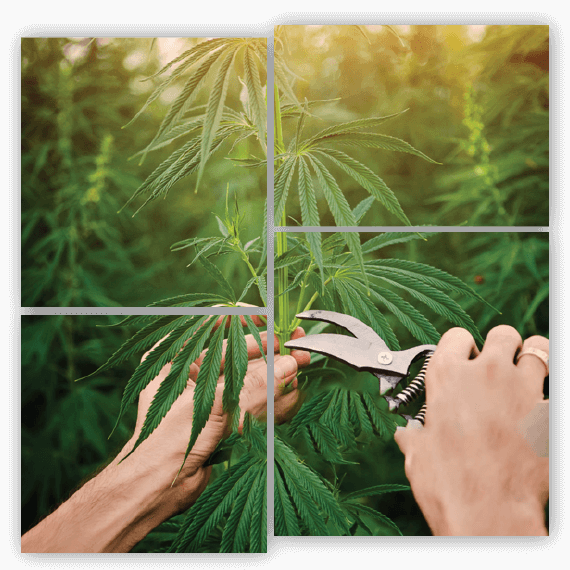

- We plant the hemp plants close together for tall growth and minimal branching. The hemp stalks are harvested once seeds begin to form.

- The harvested stalks are left in the field for retting. Retting is a natural process to break down the woody core (hurds) and soften the outer bast fibers.

- The bast fibers are then separated from the hurds using a decorticator.

- The separated fibers undergo scutching and hackling to refine the bast fibers and remove hurds.

- The bast fibers are roved or twisted to strengthen them. The roved fibers are ultimately spun into yarn. We use dry spinning for coarser yarns and wet spinning for finer, linen-like yarns. Shorter fibers (tow) are dry-spun, while longer line fibers are wet-spun.

- In the end, doubling and drawing processes help achieve the desired finesse in the yarn.

- When you place an order, we carefully pack it in strong, durable materials. We ensure it reaches you in perfect condition. No matter where you are.

- We partner with reliable shipping services to get your order to you as quickly as possible. No follow ups required.

Shipping Method: We have logistical partnerships to guarantee that you can completely relax after placing your order with us. Your order will reach you at the minimum possible time with no need for you to follow up.

Packaging Method: Our packaging methods match the strength and durability of our hemp yarns. Your order will reach you in perfect condition. We package our consignments efficiently enough to withstand all the wear and tear of a long journey, no matter where the delivery has to reach.

What Makes Our Hemp Yarn Truly Unique

At Hemp Foundation, we grow our hemp in the purest Himalayan soil. We use organic methods passed down through generations. The result? Yarn that’s as strong as the mountain roots and as clean as the mountain air.

When you choose our hemp yarn, you get:

Yarn grown 100% organically, with minimal chemical use.

The strength and durability that only traditional, organic farming can bring.

Certified quality that meets India’s national standards.

We don’t just sell yarn - we empower you to contribute towards a sustainable future.

What Makes Our Hemp Yarn From Rudraprayag Unique?

THE INIMITABLE HIMALYAN TERRAIN

The quality and purity that the Himalayan terrain offers is unmatched. That’s why our Himalayan hemp yarn is the purest that you can get. Afterall:

It is grown on soil that’s enriched by fallen foliage and the dung of grazing animals

It breaths the fresh air of the mountains

It is tended by experienced farmers who use ancient methods with modern technology

With that, the plants produce strong bast fibers, which we turn into top-quality hemp yarn.

100% ORGANIC FARMING

Uttarakhand is the 1st (and the only!) state in the country to have passed the Organic Agriculture Act (2019). With that, all farming in the state is now completely organic. No chemicals. No fertilizers.

The hemp from which we derive our yarn, is grown 100% organically in Rudraprayag.

How do we ensure good yield without artificial support? With the generational wisdom of the local farmers.

These aren’t hollow claims. We have an official organic certification from a center accredited by Agriculture and Processed Food Export Development Authority (APEDA), GOI.

Supporting Local Communities

The quality of our Himalayan hemp yarn is only a part of what it makes the best. Other than that, we also support local communities.

Rudraprayag is the perfect place to grow hemp. But where to sell the grown hemp? That’s a question that the locals found themselves asking when hemp got banned. But the global demand is on the rise.

At Hemp Foundation, we act as a bridge between the global demand and local supply. This unlocks stable income and a brighter future for the locals. Without leaving their homes or families behind for seasonal employment in the cities.

Empowering Women for a Stronger Future

Rudraprayag isn’t like the modern metro cities where men and women sit at the same table. Historically, women have always been on the sidelines. But we are changing that.

Women are the key players in farming, processing, and selling our hemp yarn and other products. This economic upliftment is creating a social impact too.

Women are finding their voice. Rudraprayag is on its way to become a more gender-neutral space, where men and women thrive alike.

Frequently Asked Questions

Read the latest property how-to guides, and information and tips for buying, selling, investing and renting.

We recommend an order of 200 kg of hemp yarn to make it viable for both of us. You can choose different variations of yarns, as long as the total is 200 kg.

We work with fast and reliable shipping partners to get your order to you quickly. However, the exact delivery time depends on the distance, delivery method, and shipping route. But rest assured, we’ll get your order to you as fast as possible.

As the number one hemp yarn manufacturers in the global hemp business, we have super-efficient logistical partnerships. We are serious about ensuring that your order gets delivered within the minimum possible time – without you having to chase us about it. It doesn’t matter where you need it delivered. However, several factors determine that time. The first is the distance that the consignment has to cover. The second is the mode of delivery you choose. Air freight will naturally reach you faster than delivery by water. A paid courier service is the fastest. The road connectivity to your place of delivery from the port of entry in your country is also a factor. The bottom line, however, is that your consignment will reach you in the least possible time.

Hemp yarns are naturally strong and durable. Our hemp yarn is more so. How? Because the hemp we use is grown in the Himalayan region, where the soil is rich in minerals, and the climate is perfect for hemp farming. Plus, the plants are nurtured by farmers with years of experience in organic farming. This results in yarns that are among the strongest and most durable in the world.