If Hemp Plastic Is So Good, Why Isn’t It Used Everywhere?

Let me start with a question that’s on the minds of many in the sustainability world:

If hemp plastic is an eco-friendly alternative to the plastics we use every day, Why isn’t it everywhere yet?

Hemp plastic is seen as one of the most promising alternatives to traditional plastic:

It’s fast-growing.

It uses less water and chemicals.

It even pulls carbon out of the air as it grows.

But in spite of all these advantages, hemp plastics still account for a tiny fraction of the global plastics market.

Why is this, and is it about to change?

I will deconstruct the reality step by step so you understand not only the benefits of hemp plastic but what’s holding it back.

What Makes Hemp Plastic Better for the Environment?

Hemp plastic is a type of bioplastic. That means it’s made from plants, rather than as a byproduct of the petrochemical industry. Specifically, it’s made from industrial hemp plants.

The cellulose is extracted from the stalks of the hemp plant. It is then compounded with other materials to create a plastic resin.

The resulting material is hemp plastic. It is a bioplastic that can then be molded and extruded just like conventional plastics.

It has proven to be ideal for industries such as sustainable packaging, automotive parts, and 3D printing.

From Freepik

The big selling point for hemp plastic is its environmental upside. Facts will make it crystal clear:

Grows Quickly

The hemp plant matures in just 12 – 14 weeks. It needs minimal water, no pesticides, and can grow on almost any type of soil.

Carbon Sink

A single hectare of industrial hemp can absorb between 8 and 22 tonnes of CO₂ annually. It is unmatched in its ability to clean greenhouse gases.

Efficient Production

The manufacture of hemp plastic requires about a third less energy on average compared to chemical-based plastics. Also, there are zero toxic residues like toluene.

All of these advantages mean that if you want a plastic that’s truly sustainable, hemp plastic is the best choice.

But why don’t we see hemp plastic on every supermarket shelf? In the next section, we shall look at the real-world barriers to widespread adoption.

Why Isn’t Hemp Plastic Common Yet?

Optimism has to meet reality at some point. Hemp plastic is brilliant on paper, but in practice, there are a few hurdles to cross.

The Cost Problem

Let’s start with the most obvious – cost.

The total cost of hemp plastic is between 2 – 3 times that of conventional plastic.

Petroleum-based plastic pellets sell for about $1.00 – 1.15 per pound, while hemp plastic costs about $2.35 per pound.

If the price drops to about $1.5 per pound, it would be widely adopted without doubt.

Petroleum-based plastic is a byproduct of making petroleum and diesel. For that reason, it can be sold very cheaply.

An unfair advantage, but one that bean counters like to focus on.

The Infrastructure Gap

Production capacity is another big issue. The petroleum industry has existed for over a century. In comparison, the modern hemp plastic industry is in its infancy.

It is unfair to compare a century-old industry with a decade-old one and expect the latter to be mass-produced.

Many farmers hesitate to grow hemp without guaranteed buyers. On the opposite end of the scale, processors hesitate to expand without a steady supply.

It is a classic chicken-and-egg situation.

The Greenwashing Trap

In the era of social media and accompanying misinformation, there is no dearth of people trying to make a quick buck. Most “hemp plastic” on shelves isn’t truly 100% plant-based.

The majority are hybrid hemp plastic blends containing only 5 – 40% hemp fiber. The rest is usually chemicals like polypropylene. This matters since hybrids cannot be composted and are actually no safer for the environment than conventional plastics.

This confuses buyers and undermines trust in hemp plastic.

Regulatory Roadblocks

For decades, the hemp plant was confused with the production of cannabis. Though both are the same species, they are bred for different purposes. Hemp plants have very low THC, the psychoactive ingredient of cannabis.

But attitudes have changed, and over 70 countries have removed regulatory hurdles. But local laws are yet to adapt, making certification costly and time-consuming.

Competing Crops

While hemp is possibly the best source of bioplastics, it is not the only source. Corn and soy dominate,

with corn alone accounting for 48.3% of the bioplastics market.

This is because corn and soy get massive subsidies and benefit from existing infrastructure. Hemp is the new kid on the block and is struggling to get past the hurdles in its way.

It is surprising that only 37% of consumers even know hemp can be used in plastics. No doubt this awareness gap will be slowly dispelled, but at the moment it poses a problem.

Cost, infrastructure, regulatory hurdles, competition, and low awareness – these are considerable barriers to overcome for a nascent industry. It explains why hemp plastic isn’t yet on every shelf. But as we’ll see next, change is already in motion.

Hemp Plastic Outlook 2025–26

If you’ve been tracking the news, you know the landscape for hemp plastic is evolving fast. The momentum is real, and it’s coming from several directions:

New Investments

Major players are betting on hemp bioplastics. BASF, one of the world’s chemical giants, is now investing in hemp additive startups like Heartland in the US.

RENW has announced ten new regional hemp processing plants. Each is capable of producing 30 tons of pulp daily, and the first will open in late 2026.

From Hemp Foundation

Growing Market

The US and European hemp bioplastics market is set to grow from $125 million in 2025 to $268 million by 2032. A growth of 11% annually is very impressive indeed. Globally, the market could reach $291 million by 2031.

Policy Push

More governments are banning single-use plastics. Canada, UK, EU, USA, India, China, Bangladesh – the list is expanding swiftly and covers 80% of the global population. A ban on plastic cutlery, straws, plates, and bags will hasten the adoption of hemp bioplastics.

Better Technology

It is heartening that hemp bioplastic processing technology is making rapid strides thanks to private sector investments.

We’re seeing new fiber-separation methods, better resin blends, and more efficient equipment, all coming together to make production smoother and cheaper.

Will Hemp Plastic Soon Be Everywhere?

Here’s the honest answer. You won’t see hemp bioplastics everywhere in 2026.

But the market is moving from niche to necessary, and hemp plastic adoption is happening in every sector:

- Sana Packaging supplies the cannabis sector with hemp-based containers.

- BMW and Mercedes have proven that hemp composites work in automotive manufacturing.

- Companies like RENW and Papacks are rolling out molded fiber trays for food and retail.

- Even LEGO has pledged to trial hemp-based materials for bricks by 2030.

This is not about hype anymore. It’s about timing. And the timing looks right.

Frequently Asked Questions

Are all products labeled “hemp plastic” fully biodegradable?

If the hemp plastic product is made from pure hemp cellulose, then it is completely biodegradable. But if it has been mixed with oil-based plastics, it will not be compostable.

Can hemp plastic compete with corn or soy bioplastics?

Corn and soy are established cash crops. The farmers who grow them receive considerable subsidies. As hemp cultivation increases and hemp plastic production scales up, it will definitely be able to compete. But it will take some time to reach that stage.

What industries use hemp plastic right now?

Packaging, car makers, and consumer goods companies are the main users. Brands like BMW, Mercedes, Sana Packaging, and LEGO are exploring hemp-based parts.

What is needed for hemp plastic to go mainstream?

If hemp plastics are to become more popular, they would need to cost less. The cheap manufacturing process is the single biggest advantage of conventional plastics. Hopefully, as the industry scales up, the price of hemp plastic will drop dramatically in the next few years.

Is hemp plastic truly better for the environment?

Absolutely yes. It needs very little water, acts as a carbon sink, and requires minimal or nil use of pesticides. Hemp plastics are a truly sustainable solution that surpasses petroleum-based plastics in every way.

Vishal Vivek

Vishal Vivek is the Founder and CEO of Ukhi, a pioneering bio-materials company dedicated to ending plastic pollution by converting agricultural waste into high-performance compostable polymers. With a background in sustainable entrepreneurship and over a decade of technology experience, he leads Ukhi’s vision to create scalable, planet-positive material solutions. Previously, Vishal founded the Hemp Foundation, where he empowered more than 1,000 farmers and advanced sustainable livelihood initiatives. His work has been recognized through awards such as the HDFC Parivartan Grant and featured in leading publications like Forbes and Entrepreneur. Times Group recognized him as a legendary entrepreneur and published his biography in “I Did IT- Vol 2” alongside social pioneers like Bindeshwar Pathak (Sulabh International) and Anshu Gupta (Goonj). Vishal has authored more than 200 articles on sustainability and hemp, reflecting his deep expertise and advocacy for regenerative solutions. His commitment to grassroots impact led him to live in the remote mountains of Uttarakhand, where he immersed himself in the lives of marginal farmers, understanding their challenges and co-creating economic opportunities through hemp-based initiatives. A deeply passionate innovator, Vishal often draws inspiration from seemingly impossible achievements: “If Elon Musk can make rockets reusable, or Dashrath Manjhi can carve a path through a mountain with rudimentary tools, why can’t we eliminate the demon of single-use plastic while uplifting struggling farmers? We will make it happen—whatever it takes.” Ukhi is proud to be supported by premier institutions including IIT Guwahati, NSRCEL-IIM Bangalore, Indian School of Business (Hyderabad), Indian Council of Agricultural Research (ICAR Pusa), and the Indian Institute of Packaging. Vishal is committed to demonstrating that business can be a powerful catalyst for global environmental and social good. Connect with Vishal Vivek

Related Posts

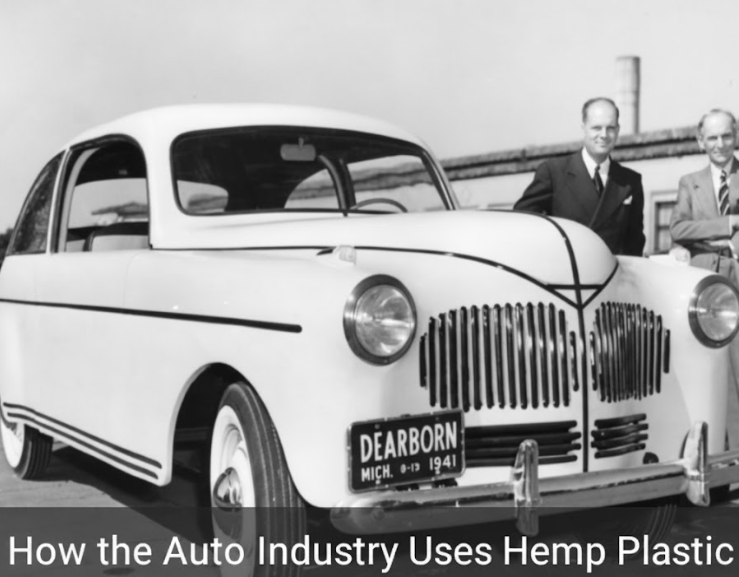

How the Auto Industry Uses Hemp Plastic

In 1941, Henry Ford built a ‘Hemp Car’. It was the first known hemp plastic automotive i

249 Uses of Hemp

Hemp is one of the most versatile and sustainable crops in the world. It is scientifically known as

Hemp Paper vs Conventional Paper Packaging

[vc_row][vc_column][vc_column_text]Choosing a greener and more sustainable alternative In the 1900s