Hemp Plastic vs Regular Plastic: What’s the Real Difference?

If I say that you’ll find plastic cups and straws floating in the holiest of rivers of India, I’ve said enough about how big a problem plastic pollution is.

Sure, nobody denies that.

So let’s talk of how we got here.

Plastic is cheap, durable, convenient, and easy to use. Left to the industry and the human need for convenience, it was always going to be a disaster.

Today, plastic pollution challenges the safety of our environment.

Microplastics have entered our food chain, water supply, and even the air we breathe.

So now, almost as a last ditch effort to salvage the situation, the world is interested in sustainable plastic alternatives like hemp plastic.

Hemp plastic is made of the cellulose of the hemp plant. This bioplastic is renewable, and biodegradable.

These properties make it a low-impact sustainable alternative to regular plastic.

So in this post, I will go into the depths of how hemp plastic is so different to traditional plastic, but is able to offer the same convenience.

What is hemp plastic?

Hemp plastic is one of the most promising players in the growing market for sustainable materials. Put simply, it’s a type of bioplastic made from the cellulose found in industrial hemp plants.

For starters, it’s a tough crop that grows fast, thrives with little water, and doesn’t need a lot of pesticides.

Almost everyone is surprised when I share evidence of how hemp actually improves the soil and captures carbon from the atmosphere as it grows. That makes hemp a material that is not just renewable, but actually carbon-negative.

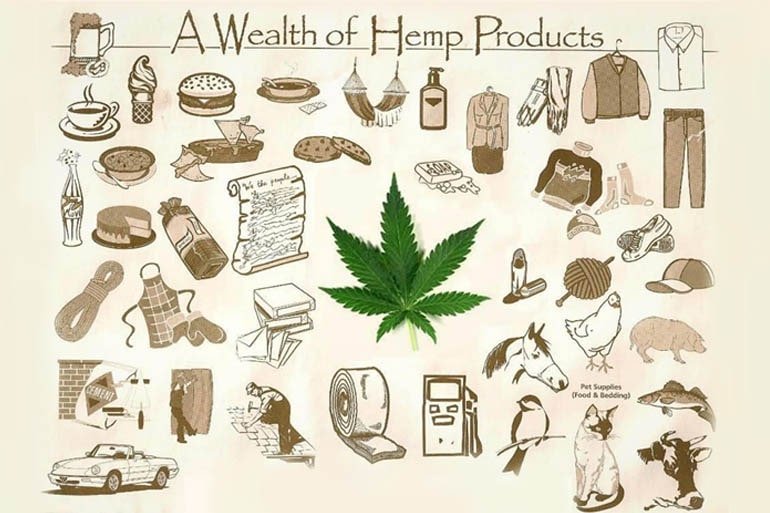

Once we harvest hemp, we can process the cellulose from hemp stalks into a wide range of bioplastics and composites. You’ll find hemp plastic in everything from packaging and car interiors to furniture and even 3D printing materials.

Why does hemp plastic matter? Here’s a quick look at what sets it apart:

- Renewable: Made from a fast-growing crop, not finite fossil fuels.

- Biodegradable: Can break down in months under the right industrial composting conditions.

- Strong and durable: Hemp plastic isn’t flimsy; it stands up well to heat and pressure.

- Eco-friendly: Requires minimal water and chemicals compared to most commercial crops.

- Carbon-negative: Absorbs more CO₂ while growing than it releases during production.

- Supports farmers: Growing hemp for plastic can boost rural incomes and drive sustainable agriculture.

The best part is that the hemp supply chain encourages a circular approach.

That’s why many see hemp plastic as a real chance to rethink our relationship with what we use, throw away, and leave behind.

How is hemp plastic different from regular plastic

Not all plastics are created equal. As more people and businesses focus on sustainability, understanding the differences between bioplastics and biodegradable plastics is key to making better, more responsible choices for the planet.

Category | Regular Plastic | Hemp Plastic |

Raw material | Derived from fossil fuels such as crude oil and natural gas. | Made from cellulose extracted from the stalks of the hemp plant. |

Common types | Polyethylene (PE), Polypropylene (PP), Polyethylene Terephthalate (PET). | Various bioplastics or polymer blends using hemp cellulose. |

Production process | Created through energy-intensive industrial processes using non-renewable resources. | Processed or blended with other materials to achieve desired performance properties. |

Renewability | Non-renewable, dependent on limited fossil fuel reserves. Requires high energy cracking and polymerization process releasing greenhouse gases. | Renewable, as hemp grows quickly and can be harvested annually. Requires less energy; however, it varies according to the polymer blend and method. |

Environmental impact | Contributes to plastic waste, pollution, and a high carbon footprint. | Carbon-negative crop; absorbs CO₂ and supports eco-conscious manufacturing. |

Sustainability | High ecological cost; limited recycling efficiency. Often leach harmful chemicals like phthalates, styrene etc. | Sustainable alternative that can reduce reliance on petroleum. Uses synthetic additives in limits. This makes it suitable for food packaging and kid’s products. |

Decomposition of material | It takes hundreds of years to decompose, accumulates in landfills as well as oceans. Moreover, it breaks down into microplastics that persist in the environment for long durations. | Biodegradable under proper conditions, with lower long-term waste impact. Breaks down into biomass, water, and CO2; no toxic residue. |

Aesthetic and design flexibility | Comparatively easier to dye and mold. It can be produced in a variety of textures and finishes. | With regards to flexibility, it offers a natural, matte finish. This could be undesirable for high-fashion brands that favour a glossy finish. |

Economic and social footprint | Mainly generates profits for oil and petrochemical industries leading to social inequities as well as ecological problems. | Supports local economies by stressing on regenerative farming. Creates distributed economic benefits. |

So, I hope it’s as evident to you, as it is to me, that to build a sustainable future, switching to hemp plastic is a crucial step.

Real-world applications and industry adoption of hemp plastic

It is time to take a look at how hemp plastic is revolutionary on the pragmatic level:

Hemp Plastic In The Automobile Industry

BMW, Mercedes-Benz, and Audi have incorporated hemp composites into production. This is because hemp plastic is lightweight and strong. It improves fuel efficiency while reducing emissions.

Hemp Plastic In Packaging and Consumer Goods

These days companies are leaning towards hemp bottles, and containers to sell goods. Personal-care brands are using hemp plastic packaging to appeal to eco-conscious customers and reduce landfill waste.

Hemp Plastic In Construction and Furniture

Hemp is strong and has natural insulation properties. These qualities make it valuable as a building block. Hemp-based items like biodegradable tiles, and furniture components can replace PVC and similar high-emission materials.

Hemp Plastic In Electronics and 3D Printing

Hemp plastics are being tested for electronic casings and 3D printing filaments. Hemp-infused PLA filaments offer a renewable and sturdy option for designers and engineers.

Hemp Plastic In Fashion and Lifestyle

Sustainable fashion brands are moving on to hemp plastic for accessories such as eyewear, jewelry, and even footwear. Brands like Hemp Eyewear produce biodegradable frames that score high on aesthetics while being environment friendly.

Hemp plastic is leading the shift towards a more sustainable future.

Myths, misconceptions, and falsehoods about hemp plastics

Greenwashing is a threat to watch out for. Yes, as a responsible consumer one has to watch out for bragging, money-driven sellers. While hemp plastic is eco-friendly, the label can be misused by the unwise. Some products labeled “hemp plastic” may contain only small percentages of hemp. In reality they are still mostly petroleum-based. Without regulations and standards, greenwashing can mislead consumers.

Another major challenge is faced during disposal. Hemp plastic needs specific composting conditions to break down. If you throw hemp plastic in a regular landfill, it may not decompose well due to lack of ideal conditions. Using the right composting technique is essential.

Scaling production is costly. Specialized equipment is required for processing the material. On top of that, the regulation bureaucracy may slow industrial growth. Overcoming these limitations require considerable effort in policy-making. Furthermore, investment in RnD and consumer demand are to develop.

What does the future of hemp plastic look like?

As research into bioplastics and hemp-based materials advances, scientists are developing new polymers that are stronger, more flexible, and able to handle higher temperatures—all from renewable sources. At the same time, governments in the EU, UK, and North America are bringing in stricter rules to phase out single-use plastics, which is speeding up this transition.

With the right infrastructure and supportive policies, hemp plastic could move from a niche solution to a mainstream material in the next decade. Its growing applications show a clear path toward plastics that are both durable and sustainable. In a world that’s becoming more conscious about protecting the environment, hemp plastic is poised to become a major player in the market.

To conclude

Hemp plastic cannot yet replace traditional plastics. It is an important step toward a cleaner, circular economy. It reduces dependence on fossil fuels, leading to lower emissions. It can be the flag-bearer for renewable agriculture.

By combining recycling, composting, and more mindful consumption, hemp plastic offers a real, workable way to reduce our impact on the environment. As innovation moves forward, it could become a key part of how we rethink the way we produce, use, and dispose of materials. It’s proof that real progress and true sustainability can go hand in hand.

FAQs

What is hemp plastic?

A biodegradable material made from the cellulose found in hemp plants. It offers a renewable alternative to real plastic.

Is hemp plastic eco-friendly?

It reduces consumption of fossil fuels, and absorbs C02 during growth. It can decompose if composted properly.

Can hemp plastic replace all regular plastics?

Irrespective of its sturdy and durable nature, it is less flexible and more expensive to produce.

How is hemp plastic disposed of?

It can be recycled or industrially composted.

Where is hemp plastic used today?

It is used in packaging, automotive parts, construction, and more.

Vishal Vivek

Vishal Vivek is the Founder and CEO of Ukhi, a pioneering bio-materials company dedicated to ending plastic pollution by converting agricultural waste into high-performance compostable polymers. With a background in sustainable entrepreneurship and over a decade of technology experience, he leads Ukhi’s vision to create scalable, planet-positive material solutions. Previously, Vishal founded the Hemp Foundation, where he empowered more than 1,000 farmers and advanced sustainable livelihood initiatives. His work has been recognized through awards such as the HDFC Parivartan Grant and featured in leading publications like Forbes and Entrepreneur. Times Group recognized him as a legendary entrepreneur and published his biography in “I Did IT- Vol 2” alongside social pioneers like Bindeshwar Pathak (Sulabh International) and Anshu Gupta (Goonj). Vishal has authored more than 200 articles on sustainability and hemp, reflecting his deep expertise and advocacy for regenerative solutions. His commitment to grassroots impact led him to live in the remote mountains of Uttarakhand, where he immersed himself in the lives of marginal farmers, understanding their challenges and co-creating economic opportunities through hemp-based initiatives. A deeply passionate innovator, Vishal often draws inspiration from seemingly impossible achievements: “If Elon Musk can make rockets reusable, or Dashrath Manjhi can carve a path through a mountain with rudimentary tools, why can’t we eliminate the demon of single-use plastic while uplifting struggling farmers? We will make it happen—whatever it takes.” Ukhi is proud to be supported by premier institutions including IIT Guwahati, NSRCEL-IIM Bangalore, Indian School of Business (Hyderabad), Indian Council of Agricultural Research (ICAR Pusa), and the Indian Institute of Packaging. Vishal is committed to demonstrating that business can be a powerful catalyst for global environmental and social good. Connect with Vishal Vivek

Related Posts

Top 50 Hemp Products You Can Get Online

“American farmers are promised a new cash crop… and it will provide thousands of jobs for Americ

How to tackle the greenhouse gas problem of textiles?

You must already be aware of ‘carbon footprint.’ And like the rest of us, you are probably eager